Tekomar XPERT Marine Engine Module

Performance. In your hands

Automated advisory on engine optimization that enables fuel efficiency and engine health supervision.

The Engine module is Accelleron’s go-to solution for engine performance optimization. It includes instant engine performance diagnostics and advisory on fuel efficiency and performance reliability. An easy-to-use interface communicates your engine’s optimization potential clearly so that you can make informed corrections.

Tekomar XPERT Marine: The desktop app

Tekomar XPERT marine is Accelleron’s all-in-one digital software solution for the marine industry that enables simple management of emissions compliance and Propulsion efficiency within one solution.

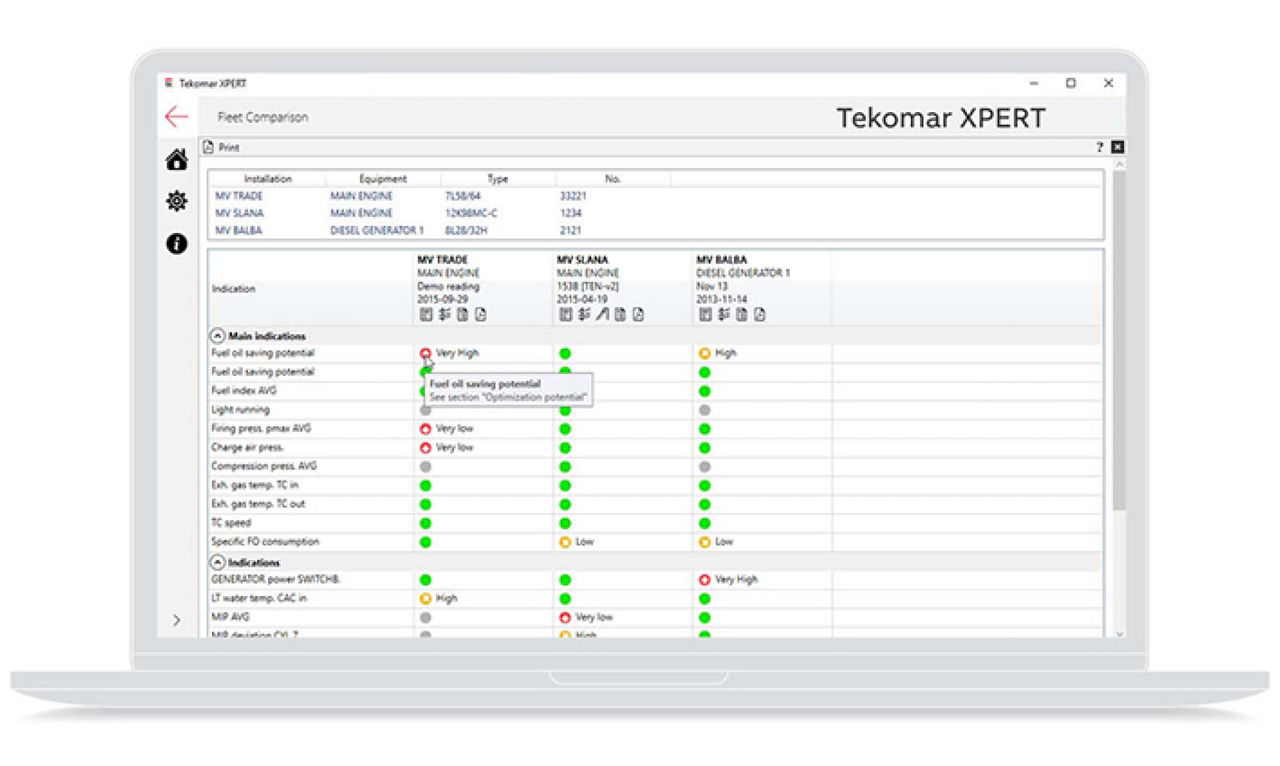

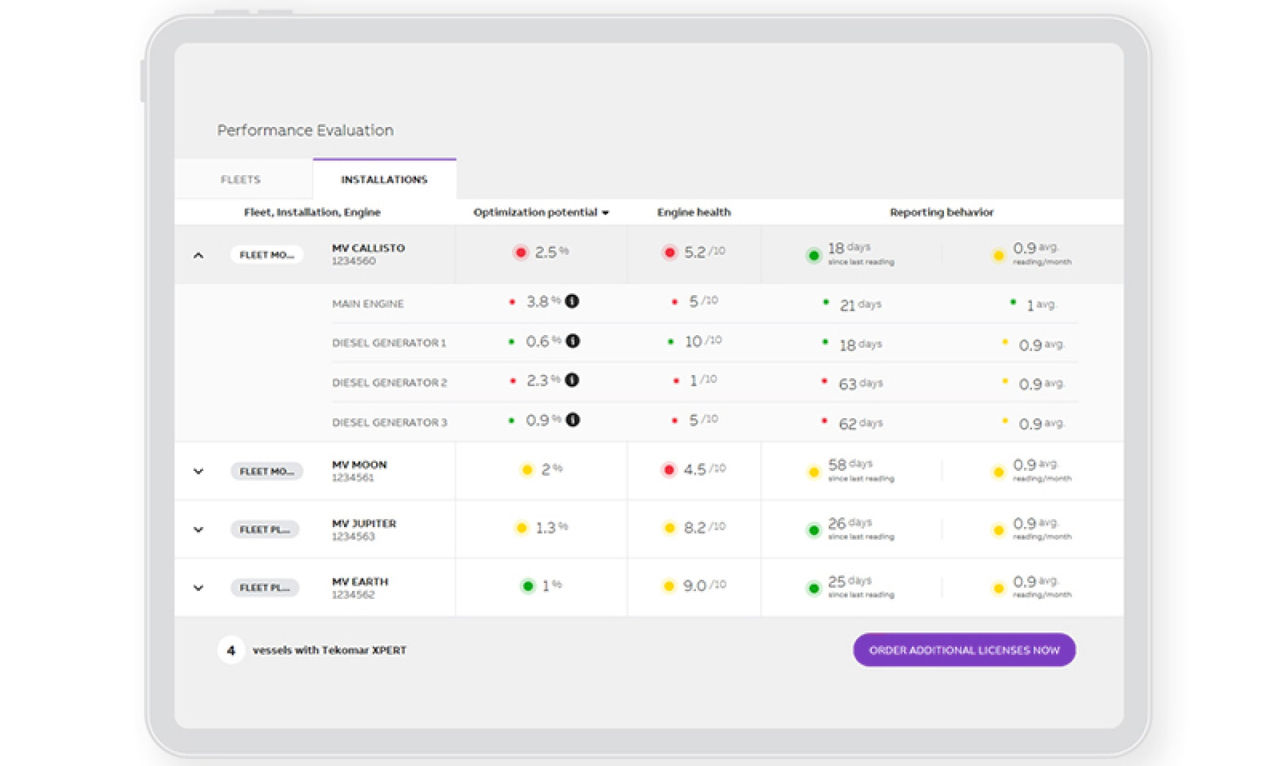

Fleet comparison

- Collate and condense engine performance across your fleet

- Quick overview and performance comparison of engines in your fleet

- Easy vizualization of performance data with the help of traffic lights

- Easily drilldown to see details for each engine

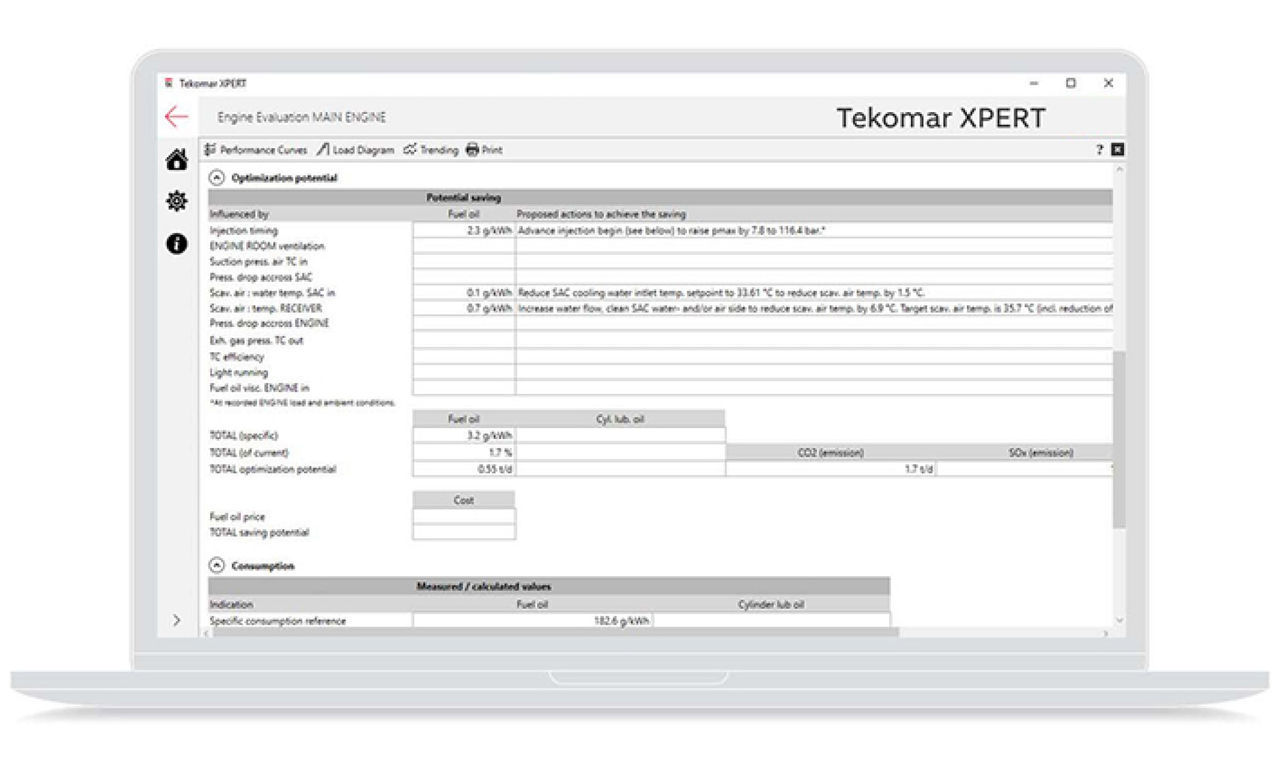

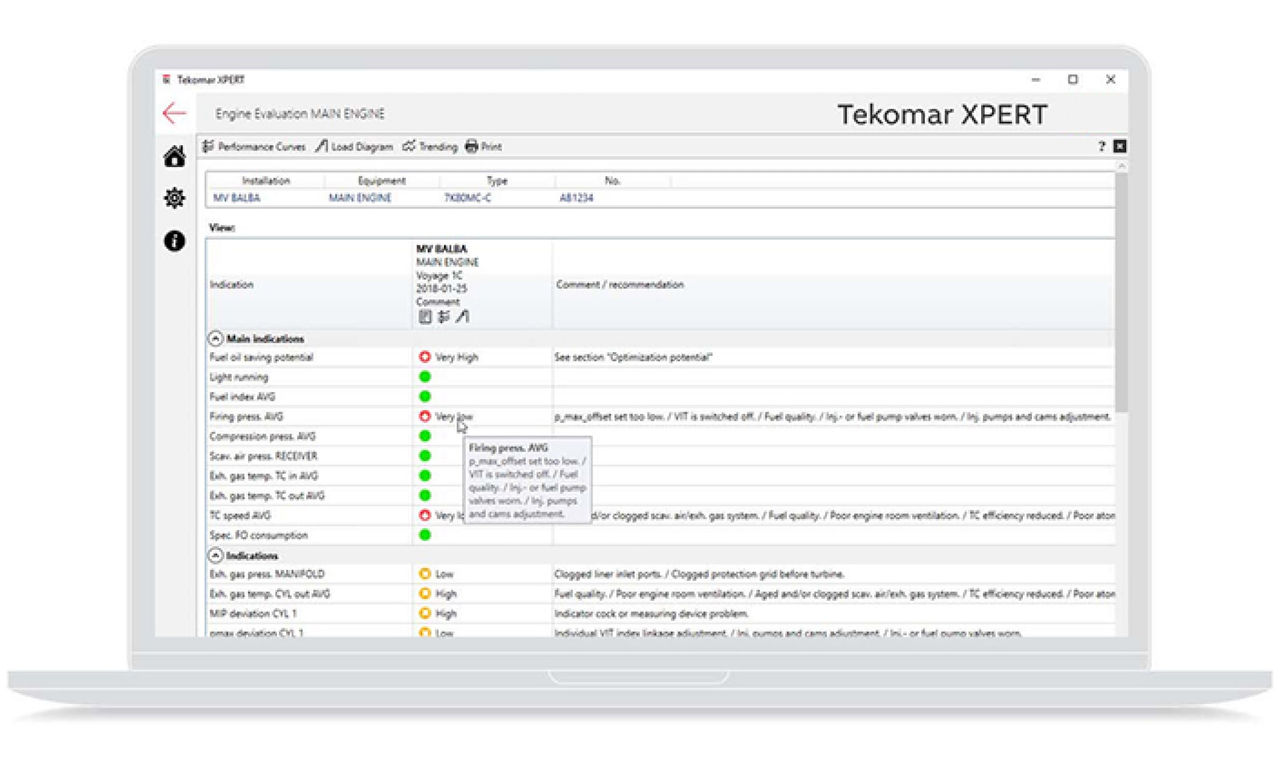

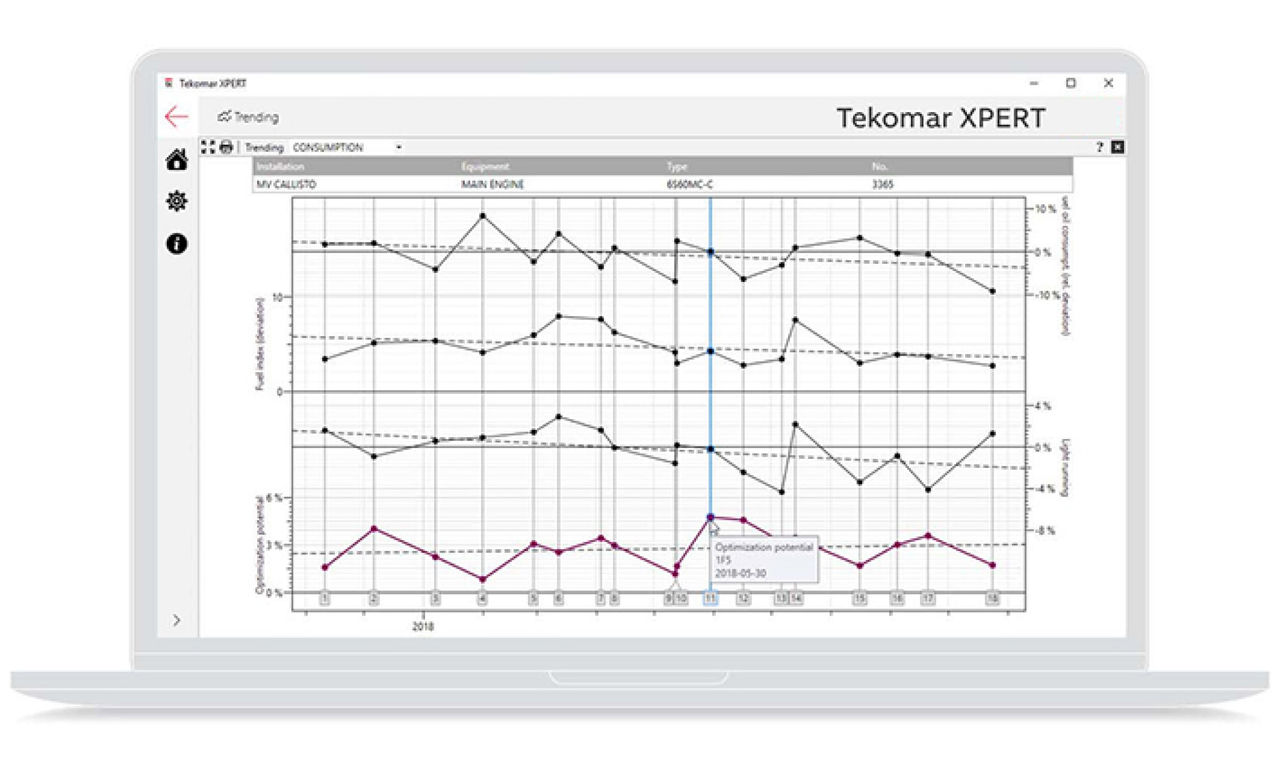

Engine Performance Evaluation in Tekomar XPERT marine

- See your engine’s optimization potential on the thermodynamic model

- Get quantified optimization potential for fuel oil savings

- Get corrective actions to take in order to achieve indicated fuel savings

Get immediate results and optimization advice in Tekomar XPERT marine

- Get a list of possible causes of deviation

- Follow corrective advice to improve performance of the engine(s) accordingly

- Engine analysis results are concise, easily understandable comments

Data input

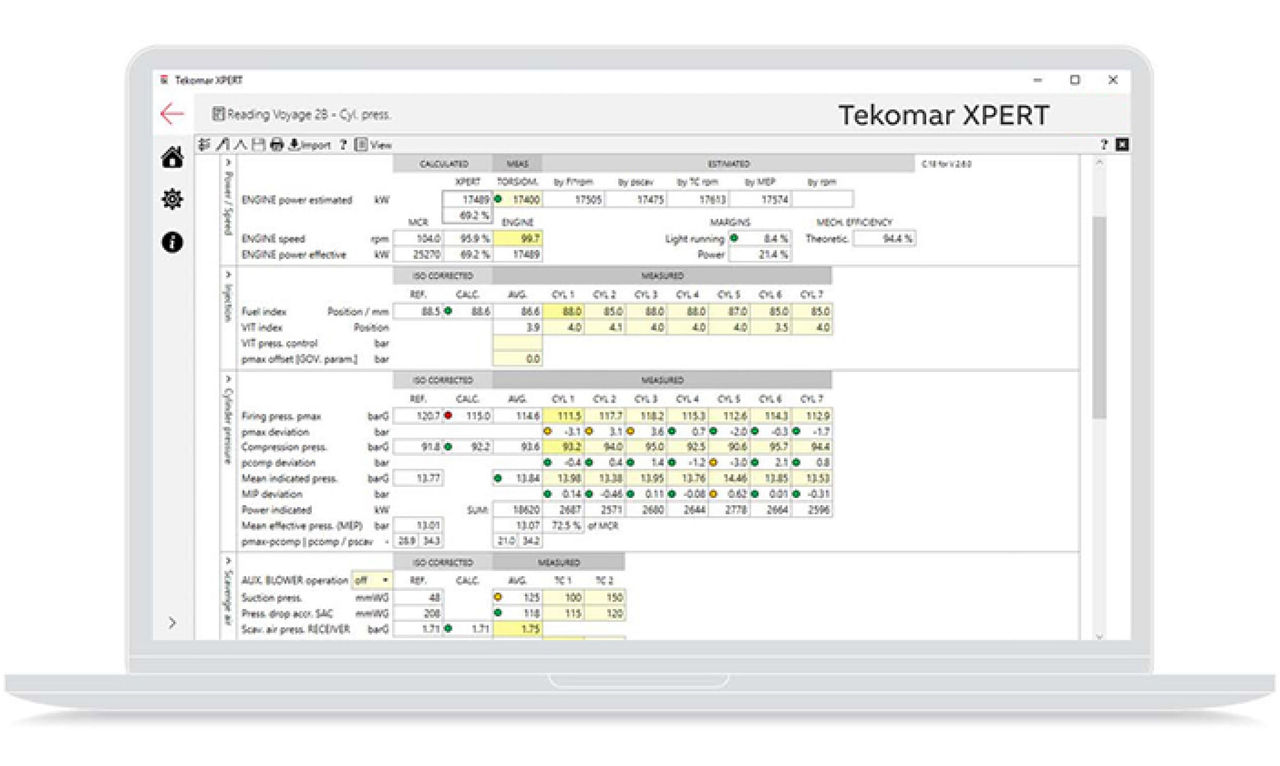

- The input form fields feature a familiar interface as commonly known from engine makers and tailored to your equipment

- Input forms feature field validation, ensuring data is captured correctly

- Calculations and references are displayed immediately once all respective data are available

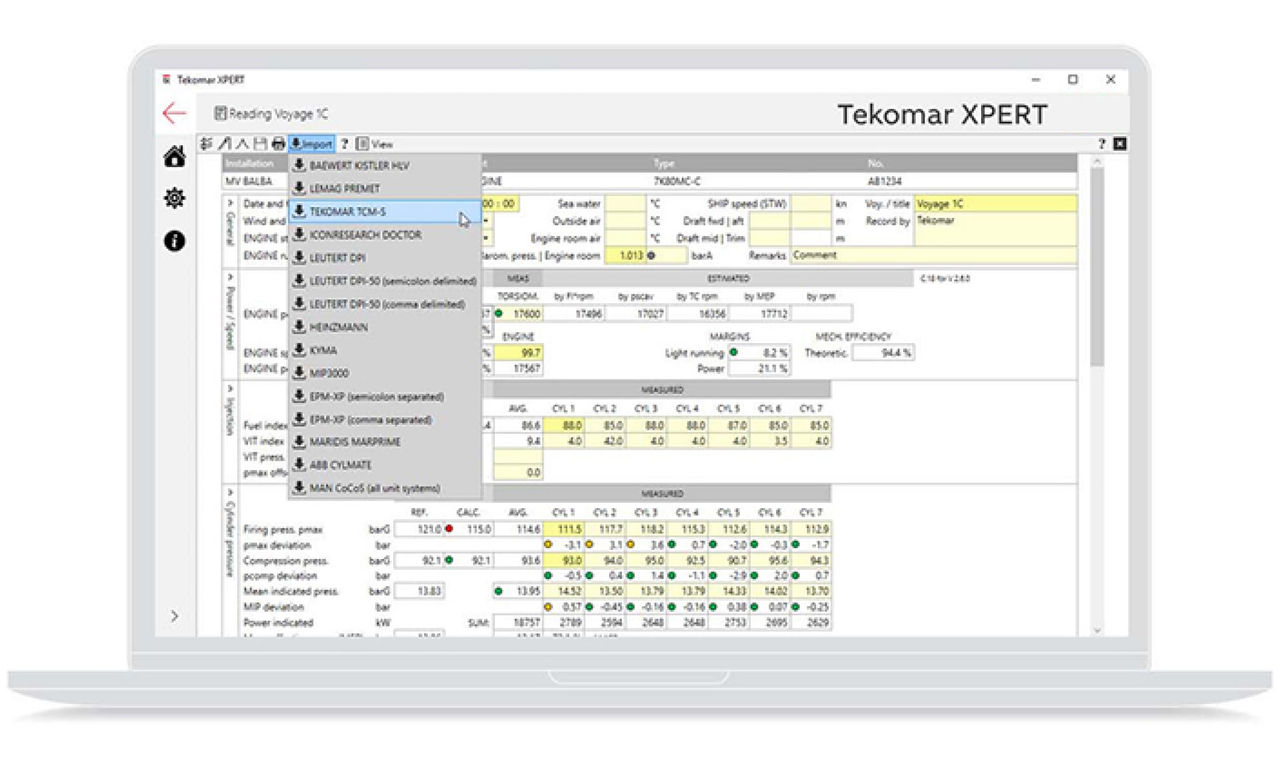

- Import data from all major DPI makers as well as from other third-party data providers

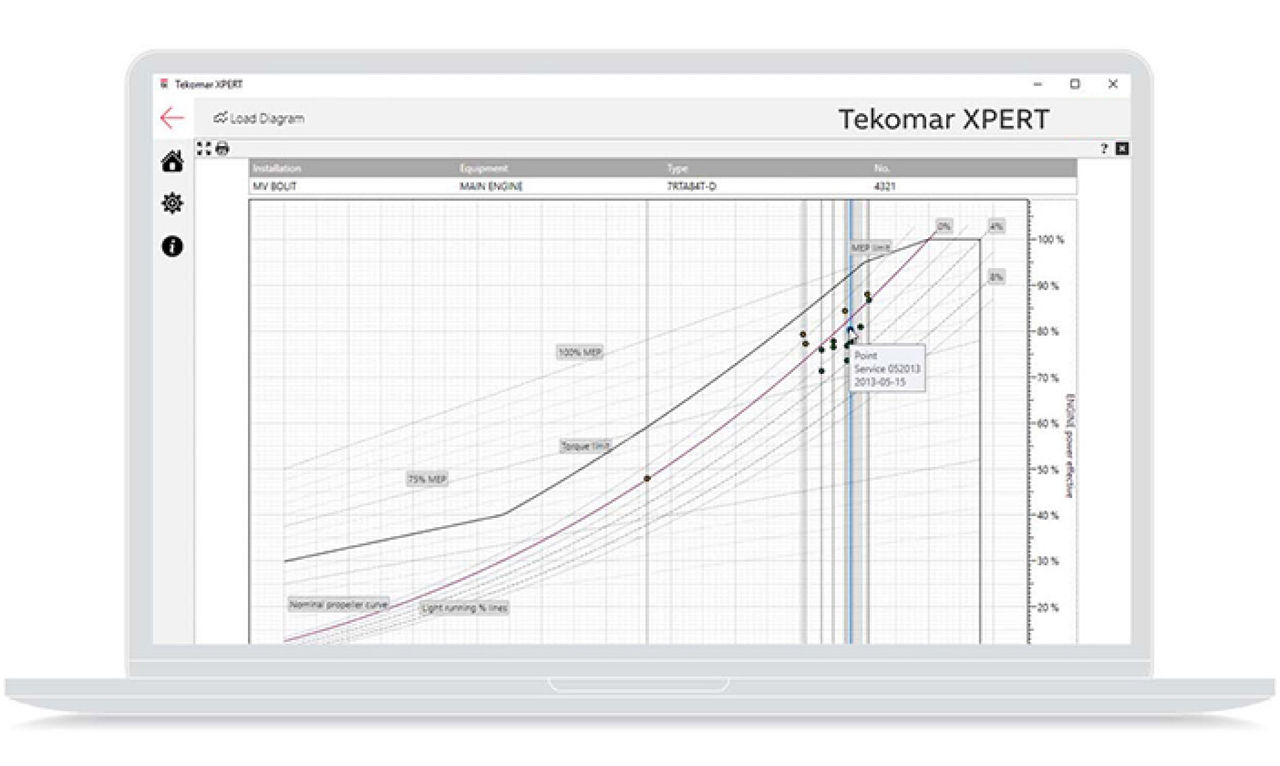

Determine engine power with Tekomar XPERT marine

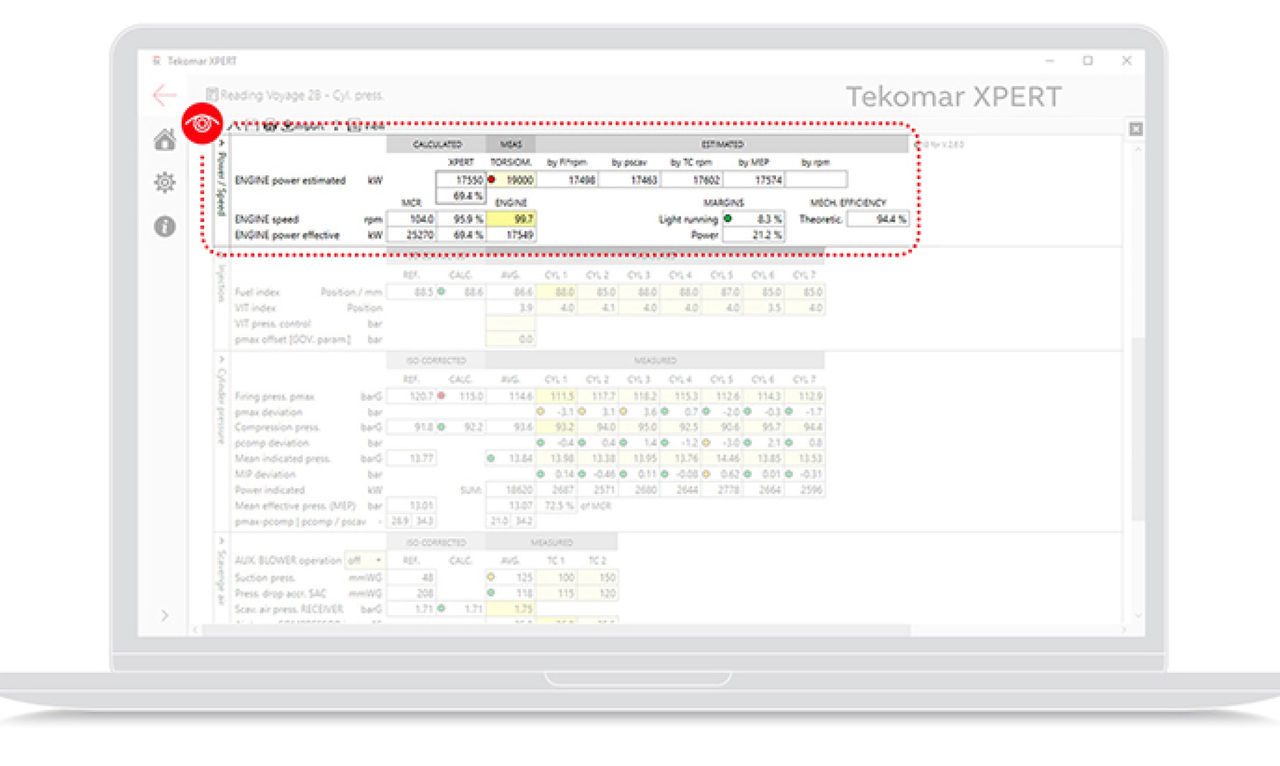

- Advanced algorithm determines correct engine power by weighing all available methods of power estimation.

- Correct engine power is the basis for performance evaluation

- Tekomar XPERT marine detects whether the callibration of the shaft power meter has drifted

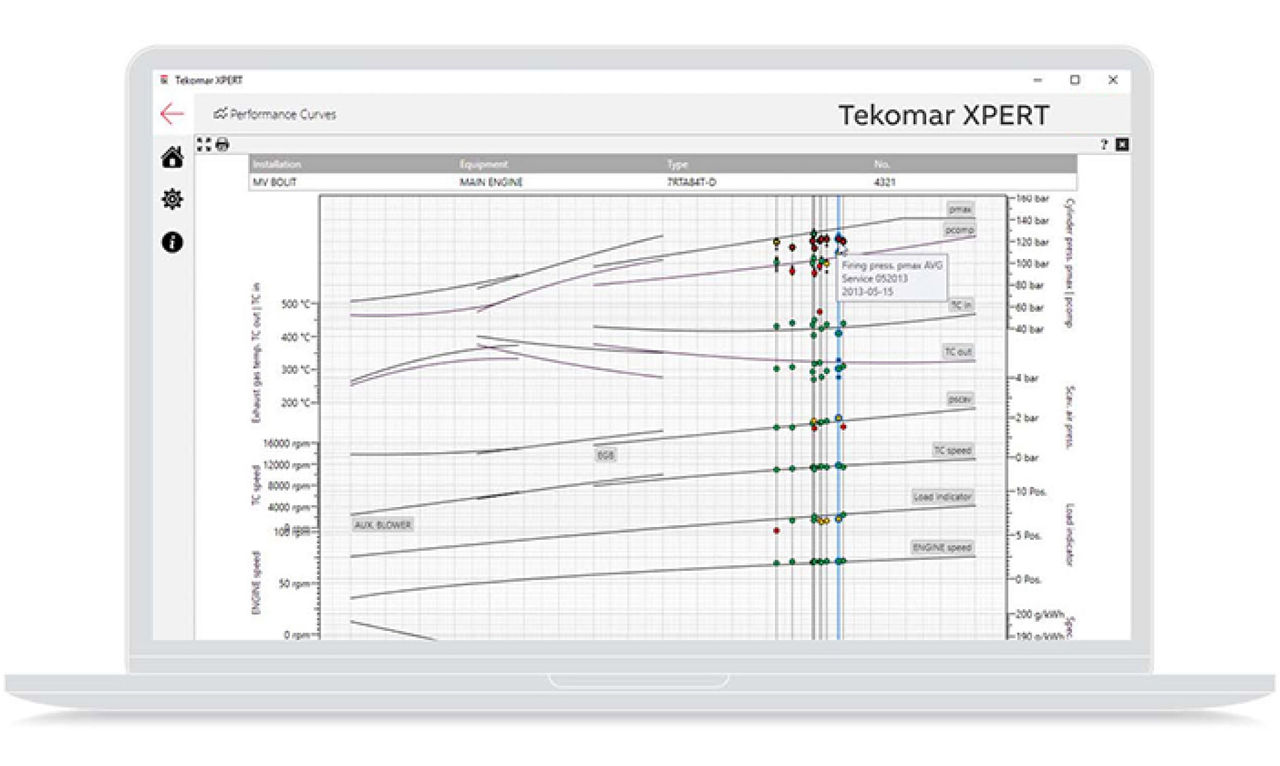

- Performance curve for comparing current performance with shop trial refference

- Performance curve for comparing current performance with shop trial refference

- Performance curve for comparing current performance with shop trial refference

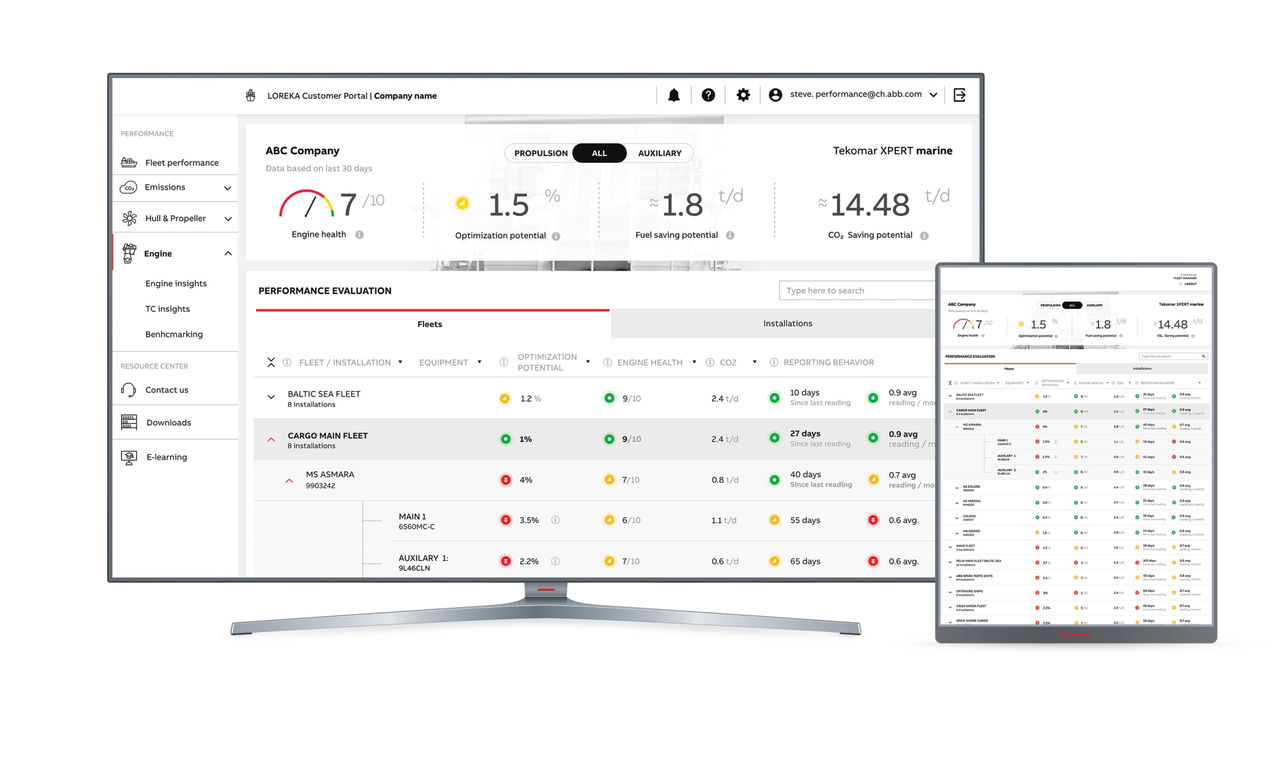

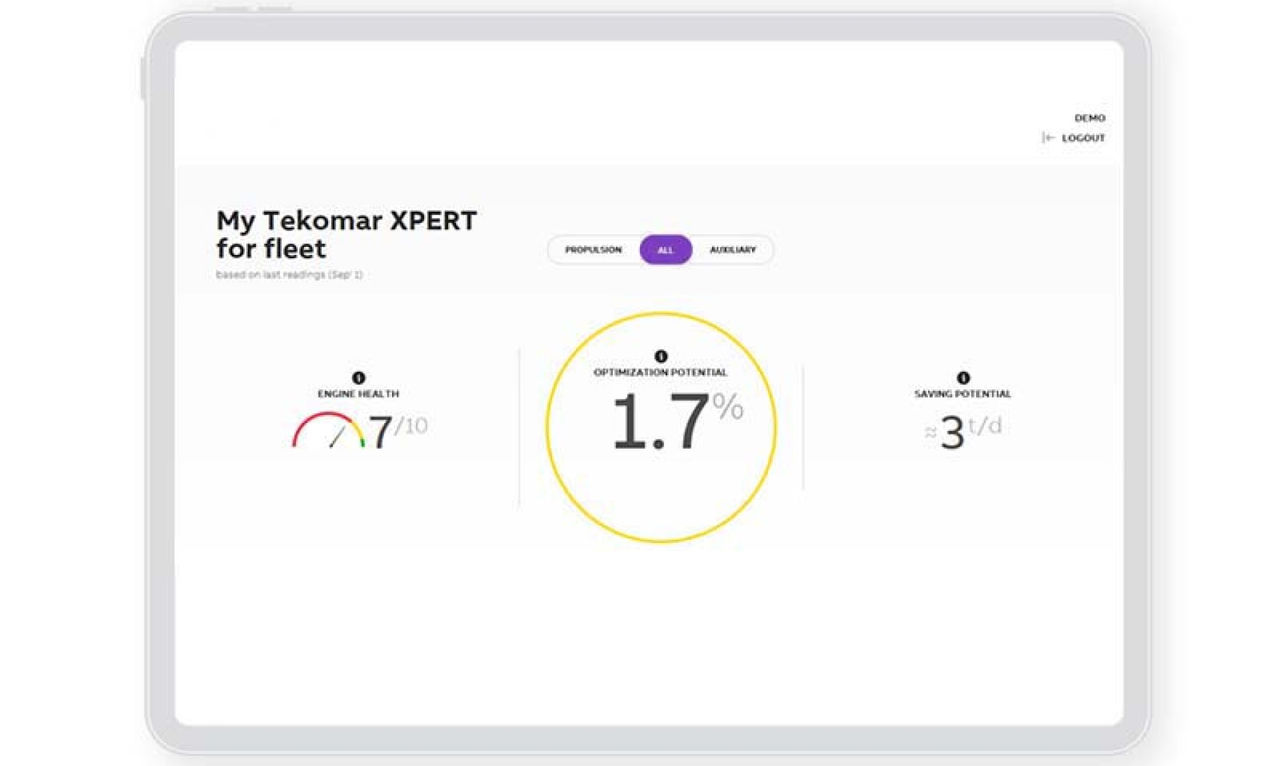

Tekomar XPERT Marine: The web app

The Tekomar XPERT web app (included in the Tekomar XPERT for fleet subscription) is a web-based application that provides a birds-eye view of the performance for all engines in your fleet. The web app which is easily accessible from any device connected to the internet presents all dat collected with the desktop app in a condensed format.

What’s more, the web app enables the benchmarking of the engine health and potential savings on fleet and vessels level, providing the technical management team indications about the status of all engines on all vessels

Feature highlights of the web app

- Overview of the engines’ performance in an entire fleet with a focus on the three KPIs: Engine Health, Optimization Potential, Saving Potential per ton/per day

- Profile-based dashboard view

Performance evaluation

- View the Engine health, Optimization potential, Reporting behaviour on the business (company) level, fleet level and vessel level.

- Benchmark Engine health and Potential savings on fleet and vessel level

- Identify high and low performers

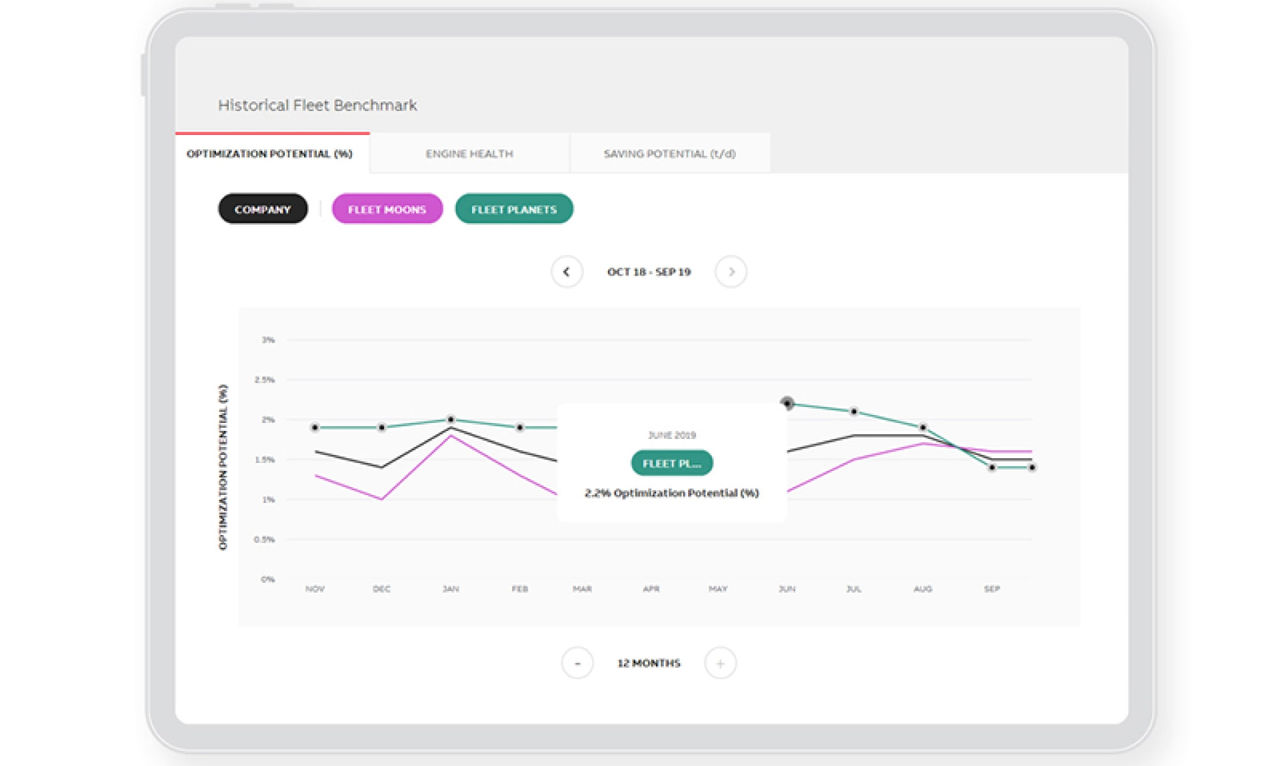

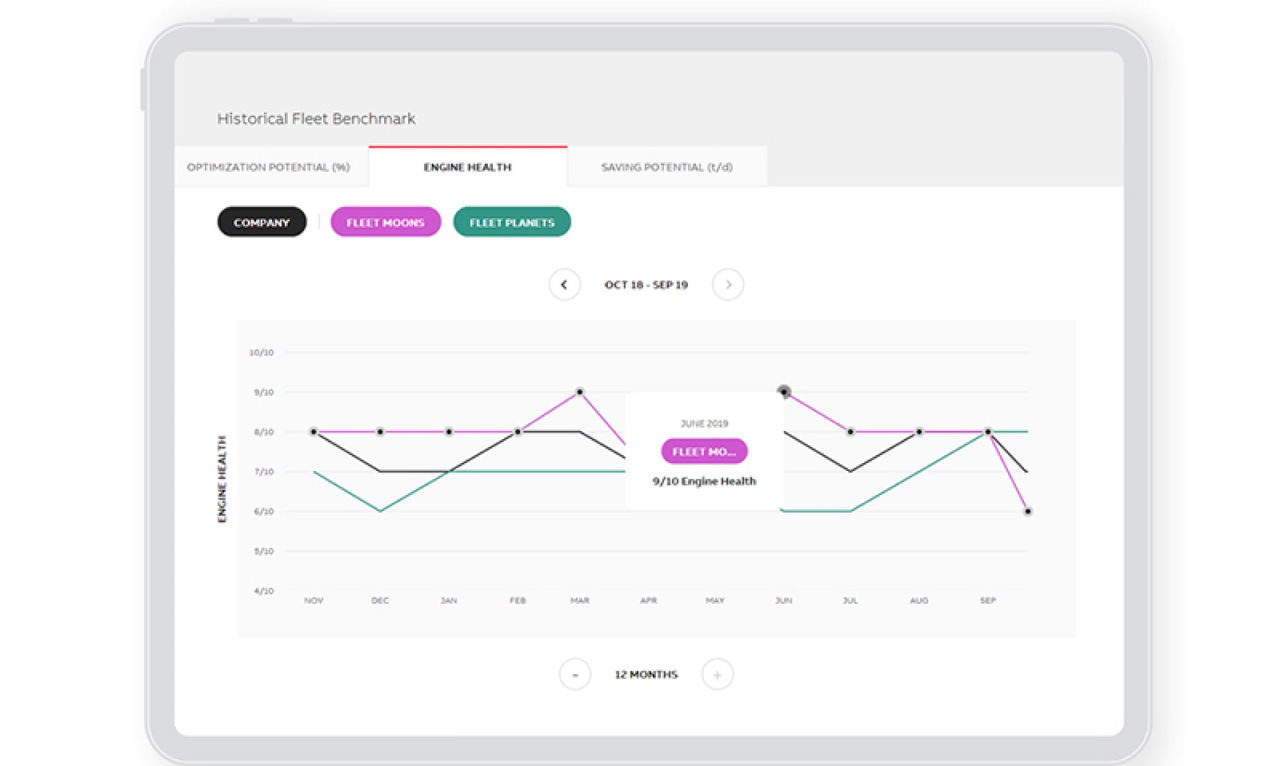

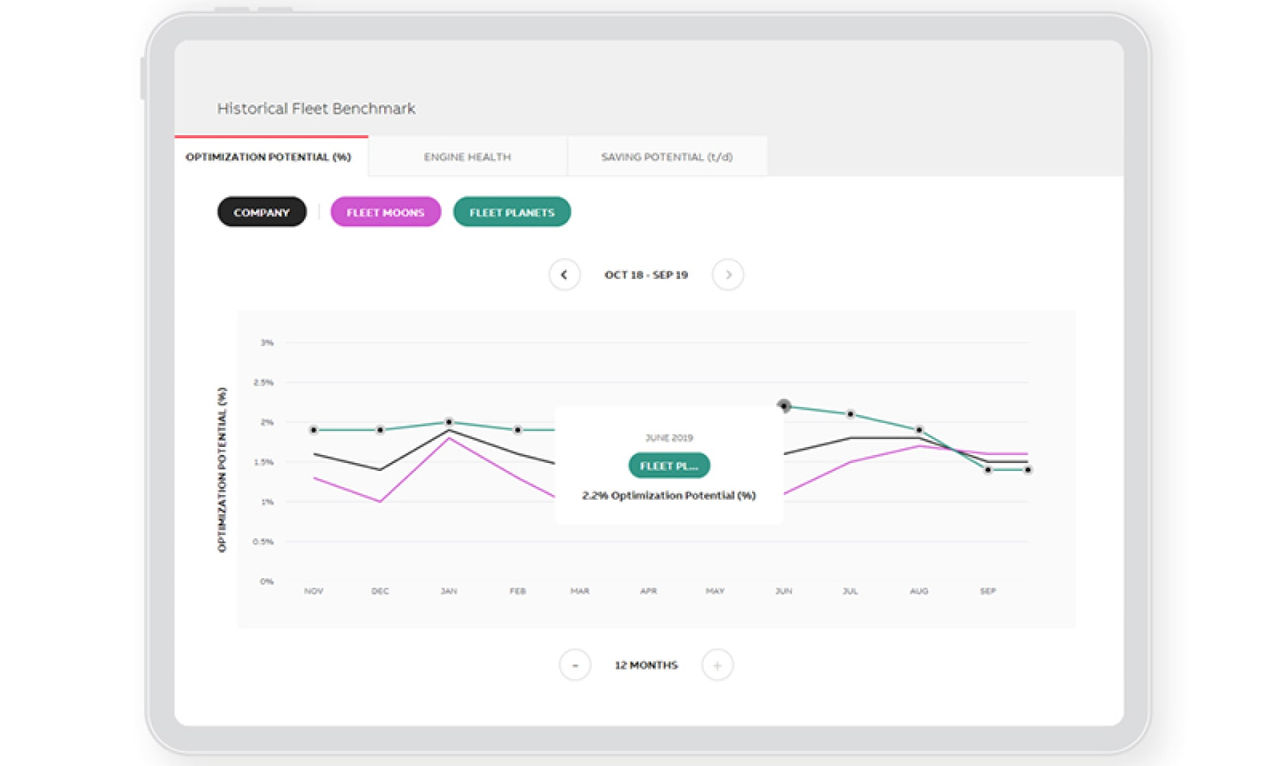

Historical fleet benchmark

- Go back in time to compare fleet performance to see trends and evolution of all KPIs

- Hover over the charts with your mouse to view details

- Compare the engine health of vessels in your fleet in the Engine Health tab.

- Compare the fuel saving potential for the engines in your fleet in the Saving Potential tab.

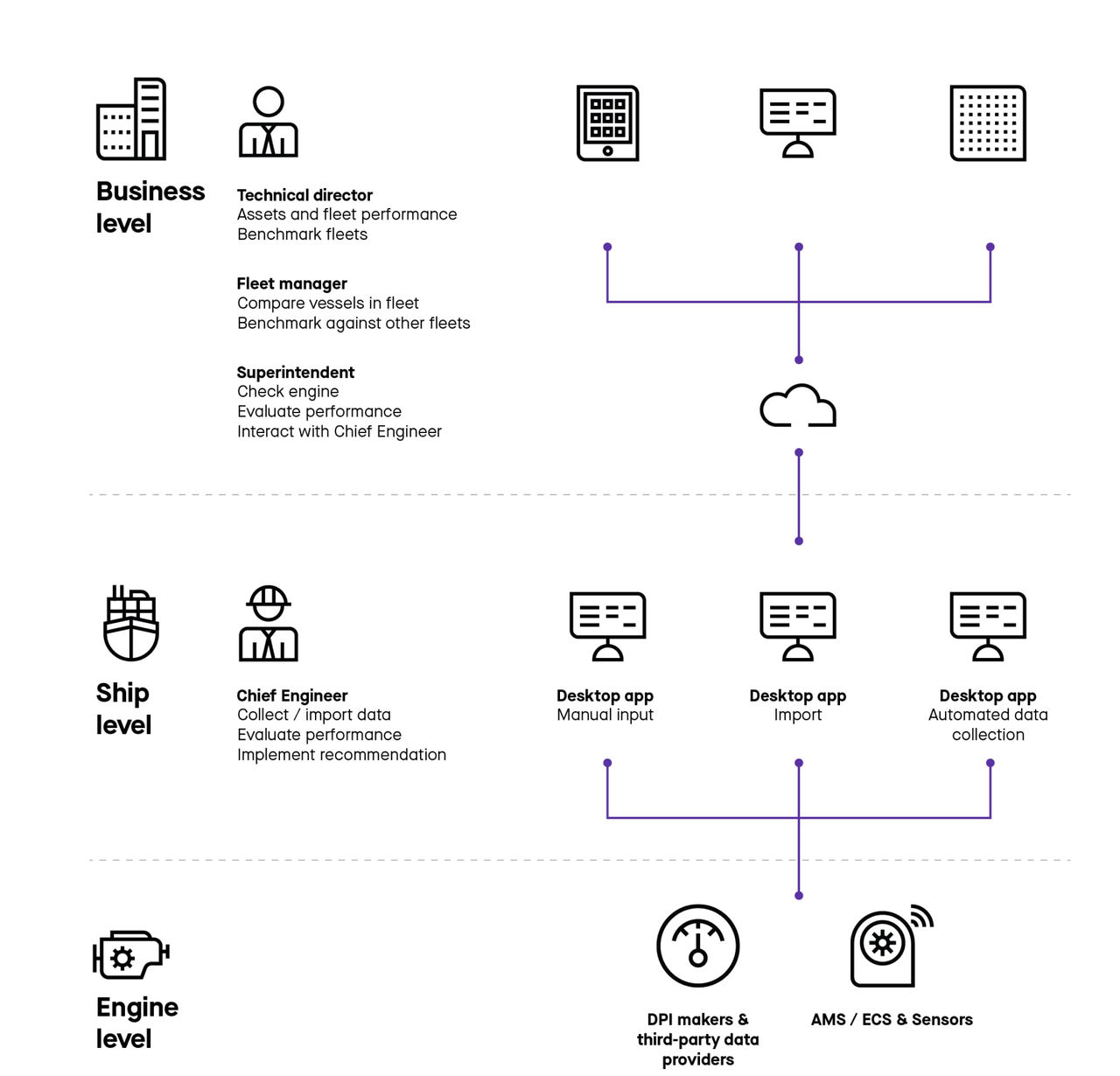

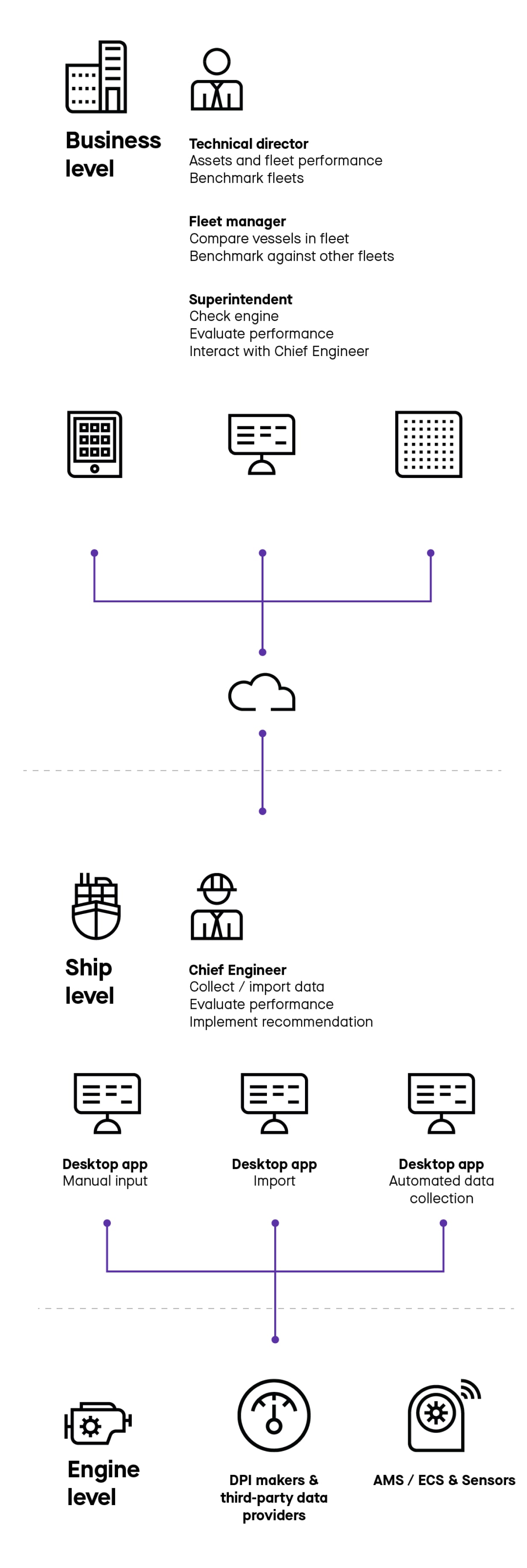

Cut through complexity with Tekomar XPERT marine

- Data is collated from the engine level, condensed and distributed via the cloud in a simplified and easily digestible format.

- Easily drill down for details.

Latest updates

Update description

The historical benchmarking page of the Engine module allows you, the user, to view the past performance of any of your vessels’ engines. Previously, you could only benchmark at a fleet level.

Listening to your feedback, we have enhanced the historical benchmarking capabilities to allow you to now:

- Compare a specific vessel against another vessel

- Compare a specific vessel against the fleet it belongs to, another fleet or the company

We've also extended the historical timeframe, so you can now analyze up to 10 years of operational data

1. Fleet 2. Specific vessel 1 3. Specific vessel 2

Benchmarking of a specific vessel against a fleet / against another

Benefits

These enhancements will provide you with more detailed insights into your vessels' and fleets' historical performance. By enabling benchmarking down to the individual vessel level and offering a longer historical perspective, you would be able to make more informed decisions about the maintenance and adjustments of your engine settings.

Update description

The Engine insights page is a useful tool for users as it allows you to see, at-a-glance, all the engines and vessels under your care. For each engine, you can see whether it is working at its desired performance level and where there is potential as well as how much potential there is for the performance of the engine to be optimized.

Previously you could only see the optimization potential of the engine as a whole. There was no indication of where the within the engine, or the ancillary support systems, that the performance could be optimized.

The new update enhances this by drilling down further into the engine performance, to various key areas that affect the engine performance including:

- Charge air cooler performance

- Fuel injection

- Cooling water system

- Exhaust gas system

We've also extended the historical view. Now, instead of just showing the current reading, you can see engine potential information and advisory for the last four readings.

Fleet view

Fleet view

Engine optimization potential view

Engine optimization potential view

Benefits

The main benefit of the new feature is that users now have more comprehensive insights into the optimization potential of various factors affecting the engines performance. This will help you to better pinpoint which areas across your fleet need attention.

The new ability to view the last four readings at-a-glance should also make it easier for you to compare readings. This would help you to potentially identify patterns in the optimization potential and make the conclusion more robust.

Background

We have been aware that in the Engine module, the engine health KPIs, which are calculated based on the number of days since the last readings, can sometimes be affected when equipment is under maintenance. During these periods, no measurements can be taken, which can lead to skewed calculations.

Update description

With the latest update, you can now set the status of any equipment as "under maintenance." This simple setting allows you to specify the duration of the current maintenance activity or any planned maintenance activity, which will then be excluded from the engine health KPI calculations.

Window for setting an equipment’s status to “under Maintenance”

- Set status to “Under Maintenance”

- Set time period when the equipment is under maintenance

- Save the status

Benefits

With this simple new addition to the Engine module, you will obtain a more accurate picture of the engine health KPIs, which will no longer be affected by the periods when an equipment is under maintenance.

Background

Close loop, electronically controlled engines typically maintain the firing pressure, compression pressure and MIP at the required levels. As such, it may seem unnecessary to have to monitor these parameters for any deviations.

As a matter of fact, the extent to which the engine control system can compensate for issues with the injection equipment, piston rings, exhaust valves, etc., will reach its limits at some point in time.

In this case, the symptoms of the underlying root cause had been covered for a long time and will finally become apparent in the performance of the engine.

Update description

As an additional diagnostic function for closed-loop regulated engines, we have developed this feature that provides a “traffic light” view of the control settings. This provides at-a-glance monitoring of the engine control settings.

Our software can now alert you when the engine control is overcompensating for issues. It identifies the root cause in the same way it would for mechanically controlled engines, where component wear directly leads to suboptimal performance.

New traffic light view of control settings

New traffic light view of control settings

Benefits

This new feature will make your job easier by allowing you to quickly see, via the colored visual display, when a particular setting of the control system tends to drift away.

Past updates

Update description

- Correct TDC in large engines can often be difficult to detect accurately

- Can lead to inaccurate Mean Indicated Pressure (MIP) reading which impacts engine performance

- New algorithm developed based on over 150'000 real world measurements

- New algorithm results in TDC detection rate improvement by a factor of 6.5

Key result

Power calculation of the engine is improved resulting in even more accurate advisory and calculation of optimization potential

The new TDC-detection algorithm is part of our normal software releases and is available with immediate effect to all our subscription customers