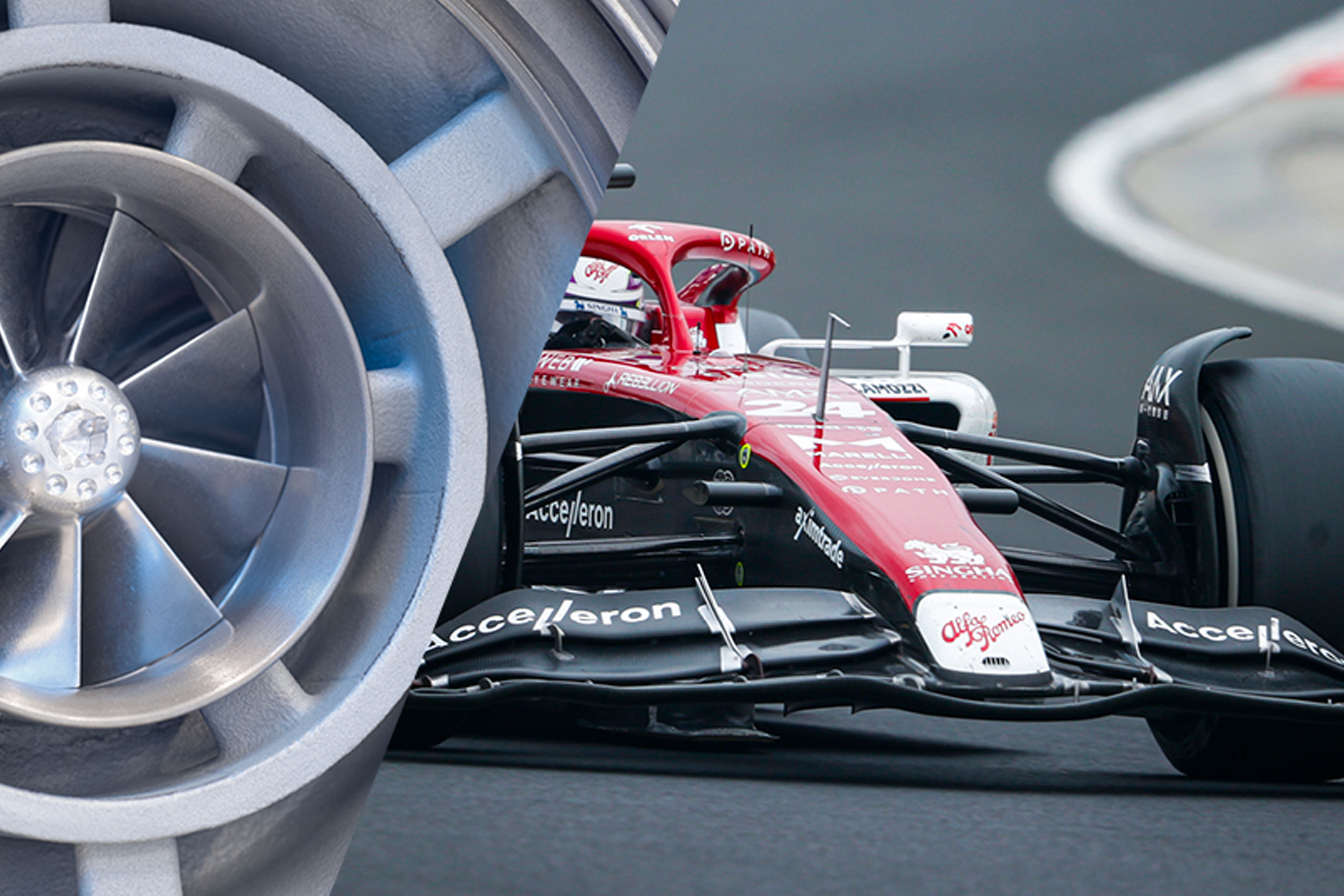

To the untrained eye, Sauber Group and Accelleron work in very different fields. A Formula One car is redesigned every season and spends more time in the hands of its mechanics than it does in its driver’s. A turbocharger is built for tens of thousands of hours of uninterrupted operation, with as few hardware upgrades as possible. But when we look beyond the visible and consider the broad, complex world of digitalization, the parallels start to become strikingly clear.

Digitizing is a very human tendency. For millennia, we’ve invented instrumentation to help turn the world around us into numbers and values: clocks, scales, thermometers. These have helped us make better decisions, such as when to plant crops or how much to sell them for.

Today, we have smaller, more precise instrumentation and connected computing power to gather, store and analyze data. But ultimately, we use data for the same purpose: making better decisions.

From the racetrack to the open ocean

To understand how digitalization bridges the gap between Formula One and Accelleron, we spoke to Cristian Corotto, Accelleron Division President Digital, about the company’s Engine Optimization Business.

He explains: “Our approach to digitalization is structured around three pillars: Harvesting operational data to optimize performance, making this data actionable for customers, and using this operational data to improve our product offering.”

To break these pillars down, let’s look at Accelleron’s Tekomar XPERT application in the marine industry, and the C42, Alfa Romeo F1 Team ORLEN’s 2022 season car.

Pillar One: Harvesting operational data

The C42 hides a nerve system of over 300 sensors – temperature sensors, pressure sensors, ultrasonic flow sensors – that transmit a constant stream of information about the car to the team at the pit wall and to Sauber Group’s Hinwil HQ in Switzerland. Sensors also perform an almost identical role throughout a digitalized ship’s propulsion system, measuring factors such as heat and pressure in different components. This raw data is fed into Accelleron’s engine-optimization software solution, Tekomar XPERT marine.

Pillar 2: Making data actionable

Operational data is only valuable insofar as it can be accessed, understood and acted upon by the right people. In the marine industry, sub-optimal engine performance wastes time and fuel and increases emissions. Crew and fleet managers need to be aware of performance loss and correct it as quickly as possible. After processing the engine data, Tekomar XPERT recommends actions crews can take to return the engine to optimal performance.

A Formula One Team must extract the same value from their data. The better this can be done, the more time-winning decisions will be taken about race strategy, tyre and fuel management or when to pit the car.

Pillar 3: Improving the product

Formula One’s on-track battles are broadcast to millions of fans. But the behind-the-scenes race for teams to enhance their car’s performance throughout the season is just as important to the championship outcome. How a team handles performance data is a critical part of this race. If you can analyze, understand and transform data into decisions faster than your competitors, there’s a good chance your car will also be faster.

But unlike a car, code and software don’t need to be physically built. Theoretically, their design and function can constantly be altered and improved – and must be for a team to stay competitive. For Cristian, this is exactly why Tekomar EXPERT is offered as a subscription service, not a finished product. “The product is constantly evolving. We can continuously improve how we handle, process and analyze data and the recommendations we deliver to the customer.” Whether at Sauber Group or Accelleron, an essential part of digitally enabled performance optimization is optimizing the process itself.

Winning mindsets

Accelleron’s new technological partnership with Sauber Group is, at heart, an opportunity for cultural exchange, adds Cristian: “We both have data as a baseline: whether that comes from a Formula One car or a ship’s propulsion system. The question to ask ourselves is, how do we develop a winning mindset based on data?”