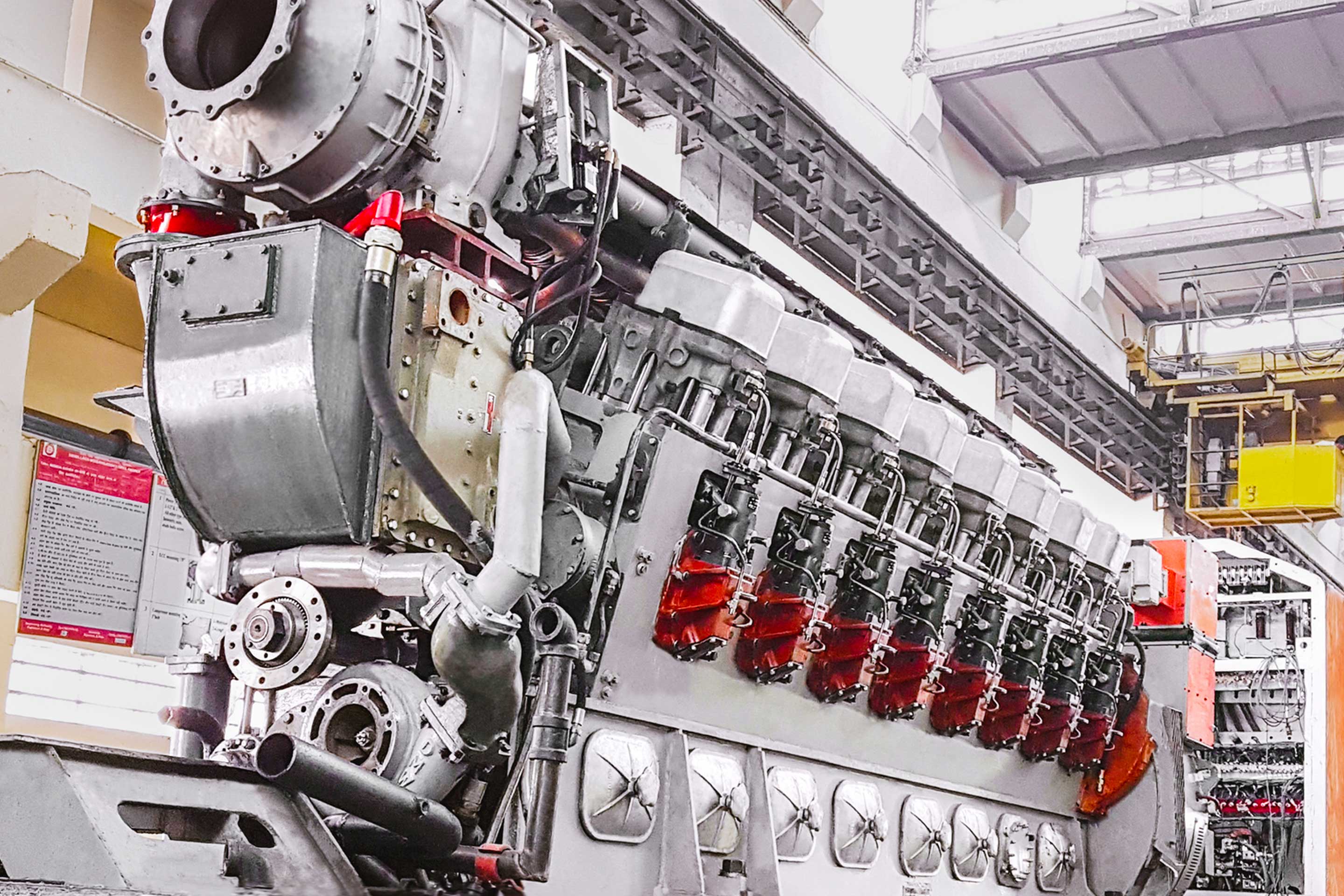

While low speed engines are almost exclusively used in the marine industry, the world of large high-speed diesel engines is far more diverse. It includes everything from highly loaded variable speed mining machinery, to demanding marine propulsion systems, to high power density generator sets, and this means that turbochargers for large high-speed diesel engines need to be far more flexible.

Developing a turbocharger for large high-speed diesel engines presents a particular set of challenges, and the large number of different applications and industries resulted in Accelleron developing the A101-R turbocharger platform. The A101-R can be customized for each different industry, covering power generation, off-highway mining, railways, and smaller marine applications.

“When we look at these high-speed diesel applications, you get an unusually large spread of requirements,” Michael explains. “It’s difficult for an engine builder, as it’s not economical to develop a unique engine for every application. Instead, they will typically develop a multi-purpose engine, providing versatility for a wide range of applications.”

Supporting different markets

A significant number of Accelleron’s turbochargers for high-speed engines are used for power generation applications, Michael explains. “This includes gas engines operating on either natural gas or biogas to generate electric power and heat for residential utilities, and gas engines in the oil and gas sector, where engines are used in compressor stations to drive natural gas through pipelines.

“Large high-speed diesel engines are used for power generation as well,” Michael adds, where flexibility and relatively low costs make them a great choice as emergency backup generators, for example, to protect data centers from power outages.

“We also have the off-highway mining sector, with all sorts of mining vehicles that rely on durable high-speed diesel engines for vehicle propulsion” says Michael.

“If you look at an emergency backup generator, for example. It can deliver the highest power rating of all applications but operates for a minimal number of hours during the year,” says Michael.

“At the other end of the spectrum, we have mining engines, which operate for almost every hour of the day, every day of the week. They operate in extremely harsh environments, facing lots of vibrations, extreme temperatures, or dust, lots of load cycles, with power always fluctuating and the turbochargers spooling up and down. This high number of engine load changes are particularly harsh on the turbocharger”.

Developing an equally versatile turbocharger

“As our high speed engine builder customers typically develop multi-purpose engines for all the above applications means that we needed to respond with an equally versatile turbocharger,” says Michael.

The result is the Accelleron A101-R turbocharger platform, which delivers the flexibility required for the diverse application portfolio of modern large high-speed diesel engines, while enabling the standardization efforts pursued by engine builders.

The concept is based on a common core at the heart of the turbocharger, consisting of a newly developed turbine stage with enhanced part load performance, a robust bearing and shaft sealing system and a solid bearing housing to turbine housing bolted joint while for the compressor side a modular design approach has been taken.

While the common core remains consistent across all applications, the modular concept results in three different application packages, comprising a) Power Generation, b) Marine, Oil and Gas, and c) Mining, Railway and Two-Stage.

“The Power Generation package is the simplest package,” Michael explains. “It’s the most cost-effective package in terms of how many dollars per kilowatt of engine power you spend on a turbocharger, as it’s not subject to the same kind of wear and tear as the other applications.

“Then we have the Marine, Oil and Gas package. This includes more sophisticated components, including a bearing housing with water cooling, for example. This is more orientated towards applications that run for longer hours, and better suited to an application that will need to be serviced and where operational costs play a much more important part compared to power generation.

“Last but not least, we have the Mining, Railway and Two-Stage package. This includes a water-cooled bearing housing as well, but also features special wear protection and sealing elements, which help to make it a very durable product during particularly harsh engine operation.”

Building a platform that’s modular helps to meet a large range of different requirements. “The key element is the multi-purpose capability,” Michael adds. “From the outside, the turbocharger always looks the same, and the changes for the different applications are internal. This means that it’s far easier for the engine builder to integrate, because all of the interfaces for the engine are in the same place.”

Complexity for engine builders is reduced, and other benefits include superior power density when used in highly cyclical applications, along with enhanced robustness based on new features for demanding applications, with Accelleron’s latest turbocharger platform providing a truly versatile choice.

The Accelleron A101-R will be available in two frame sizes – the A131-R and A136-R, and can be combined into two-stage systems as required. Both water and oil-cooled versions will be released by the end of 2023.

Want to know more? Find out about Accelleron’s range of turbochargers here