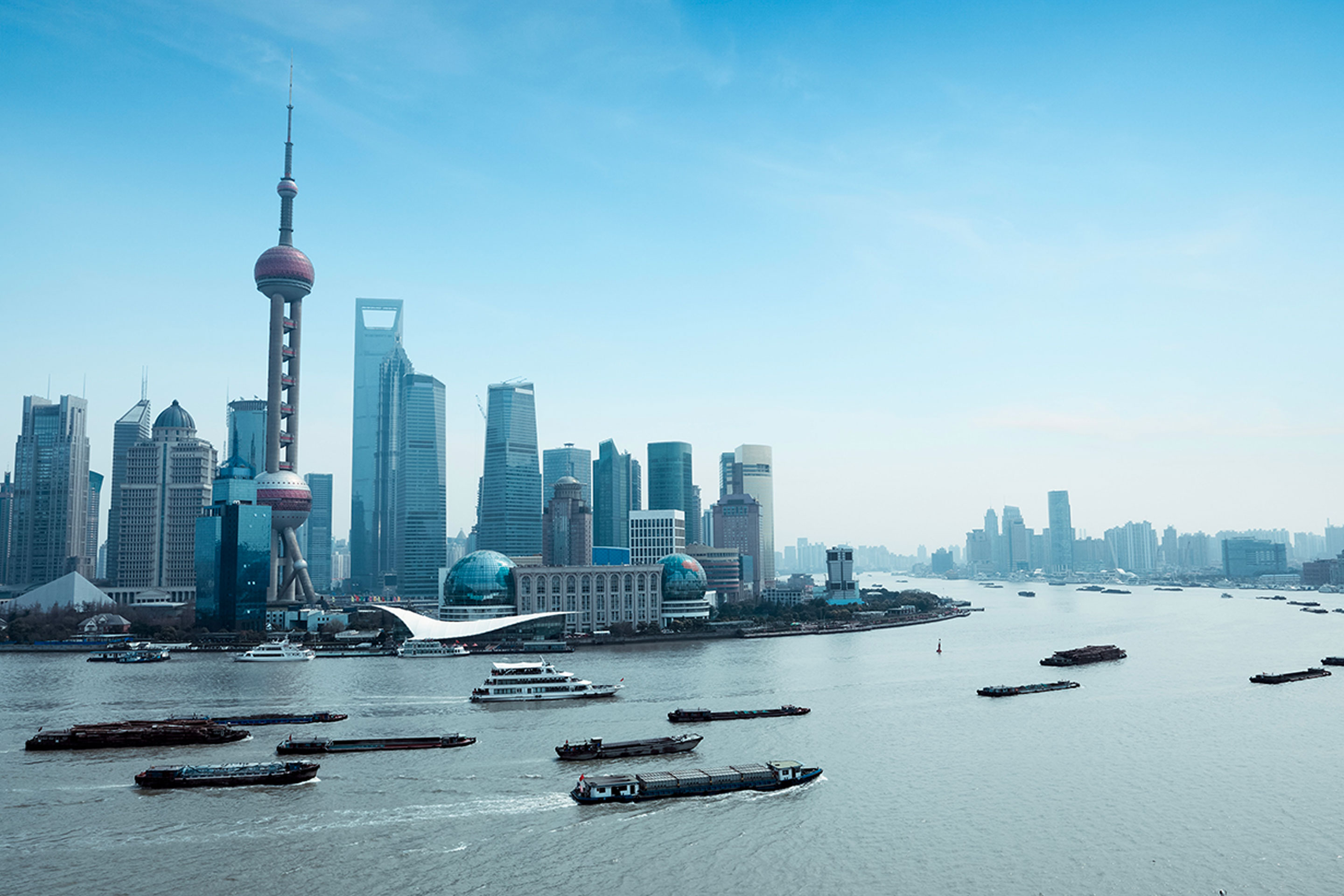

Accelleron’s country manager for China, Allan Qingzhou Wang, is looking forward to welcoming visitors to Marintec in Shanghai, the country’s leading trade show for the industry. Spanning December 5-8, this key, biannual event in the marine calendar is returning after a four-year hiatus, as the 2021 show was cancelled due to the pandemic.

Allan, who has been with the company for 30 years, says that while videoconferencing technologies have helped to plug the gap in recent times, “Meeting people face-to-face is definitely better.”

Marintec expects to host more than 2200 exhibitors and over 70,000 visitors, with the event acting as an important meeting place for Eastern and Western suppliers and shipbuilders to see each other’s offerings and negotiate deals. At the Accelleron stand N1E4A, the team will be eager to show off the last four years of new innovations to customers. This year is a milestone for Accelleron in China, marking 45 years of its engagement in the development of China’s shipbuilding industry, with its presence in China starting from Hong Kong but now across multiple offices, manufacturing site and service centres on the mainland.

“Accelleron has four large customer segments in China,” Allan explains. “It definitely starts with shipping and shipbuilding – both drive for the extensive marine engine manufacturing activities in the country. Consequently, we have a close relationship with marine engine manufacturers based in China. Those are the largest. But we also work extensively with the railway industry and locomotive engine manufacturers, which have grown in the last two years, and with the oil and gas sector.”

The Chinese shipbuilding sector is currently very strong, having overcome the setbacks created by COVID, says Allan: “China is currently the top-ranking country in the world for new ship orders. Clearly, the COVID-19 pandemic was a disaster for every industry. But people in the local shipbuilding industry have really worked hard to compensate for the deficits that created, so at this point, the industry is almost at the point it would have been if that never happened.”

Allan Qingzhou Wang

Allan Qingzhou Wang

The road to zero emissions

Decarbonization in shipping is as pressing a topic in China as anywhere else, says Allan: “Shipbuilding is a global business – 80% of the ships built in China are for export to other countries. So the pollution and emissions standards and levels that apply to other countries are equally applicable to our local industry, namely those set out by the IMO. For local shipping companies, there is a broader choice of priorities. However, the largest fleets, like Cosco Shipping or China Merchant Shipping, need to publish figures in their ESG reports and are subject to public scrutiny.”

Allan says that, in some ways, every shipowner is seeking to reduce emissions. “They have been investigating possibilities for more efficient engine designs and other technologies beyond engines like air lubrication or wind sails for years. The newest stage is moving towards new, less carbon or carbon-free fuels, and creating the supply chain to ensure those fuels are available at the docks. The largest fleets have already ordered new ships based on methanol, and others are experimenting with biofuels. The supply chain required to service these new-generation ships is well underway, with already planned capacity of producing 7.5 million tonnes per year of green methanol in China.”

Chinese ship operators are also hungry to reap the benefits of digitalization, with leading fleets investing very heavily in the area. “We have worked to make our own digital offering, Tekomar XPERT, compliant with local data regulations and are already offering it on a pilot basis for several ship operators.”

Compared to the USA and Europe, China has an unusual large reliance on river shipping. “Inland shipping accounts for 9% of all cargo movement in the country. And where it is possible, it is very much preferable to move goods by ship: it is by far cheaper than rail or road transport, by a factor of 2-6 times. This has heavily industrialized river areas, of course, so standards for emissions and pollution will become even more stringent than those applied to international ocean shipping in the future.”

“The engines also need to be highly adaptable, moving from upstream to downstream sailing, for example, which offers very different conditions. The engines are working at relatively low load most of the time, and the ships operate two propellors, rather than one, as is typical for sea-going ships. So, the engine and the turbochargers must be heavily optimised for efficiency in these conditions. But Accelleron is very much committed to serving the needs of this local segment.”

Going to Marintec? Be sure to meet up Allan and his team at stand N1E4A