Technology providers are pedalling harder than ever to meet the accelerating product development cycles needed in shipping’s drive towards decarbonization.

Confronted with an emissions target that is unachievable with current technology, marine equipment manufacturers are working full throttle to deliver new solutions. While ship operators will not need reminding of the overwhelming array of options facing them as they look to decarbonize their vessels, the accelerated pace of innovation is also adapting the way that technology providers are developing equipment, with important implications for end users.

Getting ship technology to market fast is no easy feat. As Christoph Rofka, President of turbocharger company Accelleron’s low- and medium-speed division notes, the safety and reliability demands of maritime mean that the modern approach of ‘minimum viable product’ – launching a trial version of a product with just enough features to be usable by early customers – is simply not applicable.

“We’re not software developers,” Christoph says. “When you’re dealing with iron and high-speed turbomachinery, you can’t release a product that might or might not work.”

That need for ironclad safety and reliability has traditionally meant long product development cycles for maritime machinery. But as Christoph points out, current cycles are anything but conventional. The days of taking five years to develop a product that was tightly defined at the start of the process are long gone as operators seek to comply with environmental regulation that demands big steps in efficiency each year.

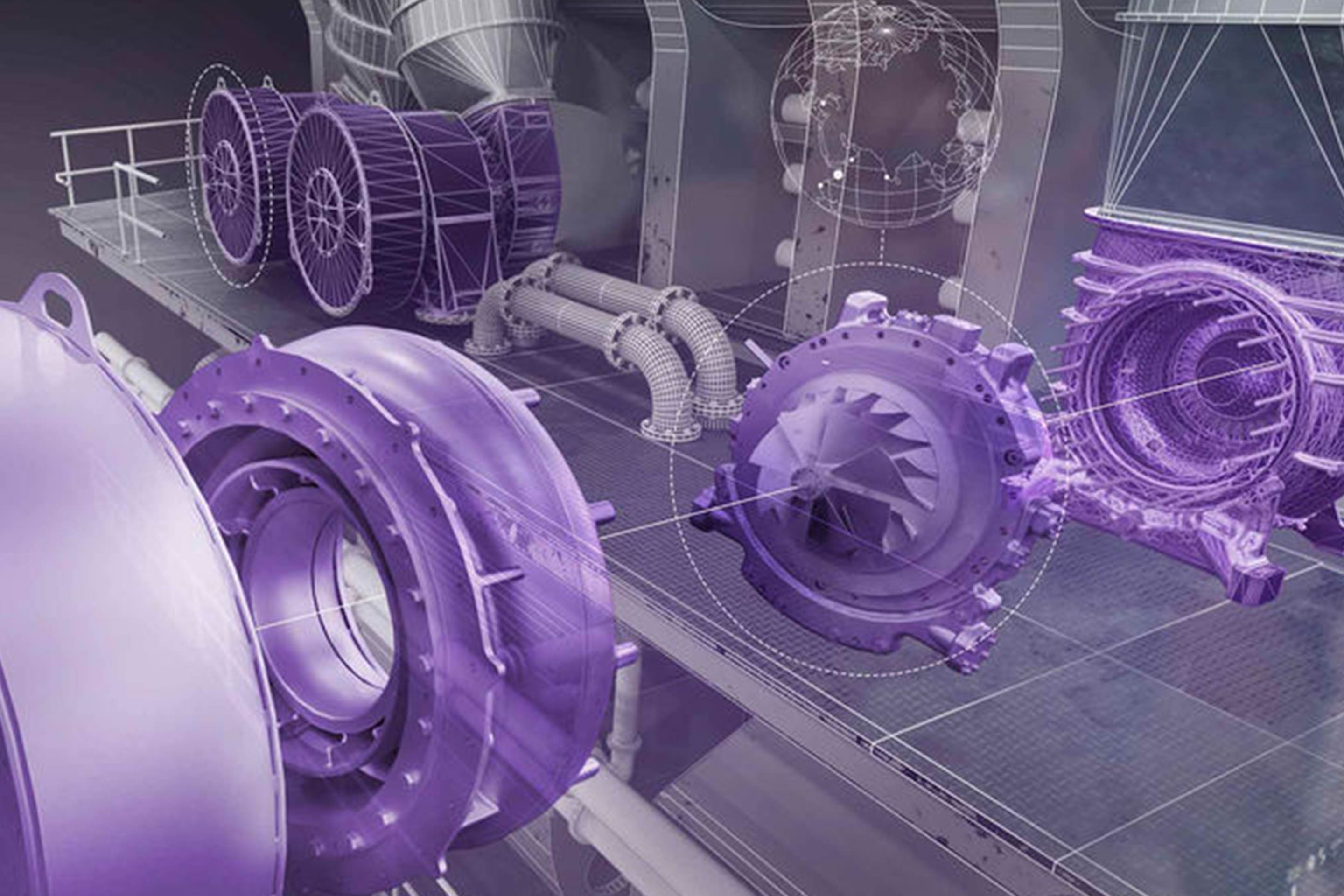

For Accelleron’s latest product release, the ACCX300-L series of low-speed turbochargers, the company tried to break the conventional cycle. Christoph explains that the supplier realised it had to “learn how to learn fast” and how to incorporate those learnings into its offering quickly.

Decoupling product and development

“Five years back we started to develop core components ahead of product development,” he says. “We used to run this in parallel, with the consequence that the biggest risk, qualifying the rotor, came very late. We gave the designers more freedom to fail, and they came up with something we did not think was possible in such a mature technology.”

The result was a big reduction in the weight of core components, improving power density – a pre-requisite for any new turbocharger generation – but also serviceability. The reduced weight meant that the components can be more easily handled by crew on board and, combined with a new cartridge-based design, can be totally replaced in a regular port stay.

That decouples turbocharger servicing from the drydocking schedule and allows operators to use the full time between overhauls, potentially cutting major service incidents from four to three over a 25-year period. It also means that users can easily upgrade turbochargers in case of new technology improvements or, crucially, in case they switch to using new fuels.

The design challenge is multiplied for products designed to be installed on existing vessels, rather than during the initial shipbuilding. Regulations like IMO’s Carbon Intensity Indicator are encouraging ship operators to give more consideration to mid-life efficiency upgrades including the installation of energy saving technologies. And, as Maersk’s plan announced this week highlights, engine retrofits are also emerging as a means to ensure that in-service vessels can meet longer-term emissions targets and reduce exposure to carbon price measures.

Reducing complexity

Modularity is at the heart of the Accelleron ACCX300-L turbocharger series. The ability to switch out the entire turbocharger for either servicing or fuel upgrades is a key feature. As well as the reduced size of components, this is also supported by a dramatic reduction in the number of components that Accelleron needs to adapt.

The entire power range of low-speed engines is catered for by just two turbocharger sizes, as opposed to five sizes for the previous A200 series. This means that the company can focus on developing fewer versions of each product, and that the service exchange pool of each component can be applied to more vessels, improving availability for operators.

Reducing the complexity of the product portfolio in this way was only possible due to the component developments achieved under the Accelleron’s accelerated innovation process. The upper power ranges of large engines are catered for thanks to a new twin turbocharger concept – only achievable thanks to the greater power density of the ACCX300-L series – that can offer considerable weight and footprint advantages compared to a much larger single turbocharger.

Cutting down the number of components developed and deployed has other benefits too. Twin turbochargers means more flexibility in cut-out options, where turbochargers are stopped or run at lower speed to increase the pressure of scavenging and compression air. This flexibility will support ship operators as they seek to either run vessels at lower loads to reduce fuel consumption, or as they need to operate on expensive alternative fuels at maximal efficiency.

Fuel flexibility and an increased demand for mid-life upgrades are fundamental aspects of the move to decarbonised shipping. As developments at Accelleron and Wärtsilä, technology suppliers are working hard (and fast) to make those changes as simple as possible. For ship operators, the shift will necessitate closer collaboration with the companies whose technologies they use, and a longer term perspective – ideally from initial design stage – on their vessel’s technical pathway to zero emissions.