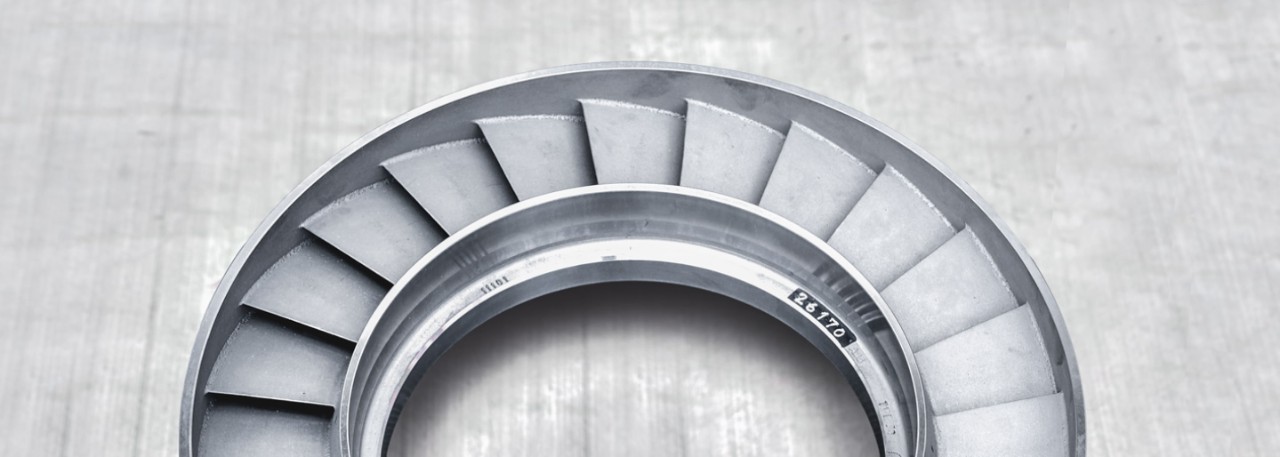

Going further with super-efficient coated nozzle rings

The task

Nozzle rings play a crucial role in turbochargers by converting exhaust gases into kinetic energy to enable stronger combustion. But they need regular cleaning to perform efficiently. Washing can also mean 60 hours of reduced load each year. For a fleet of 15 vessels, for example, that could mean as much as $3,150,00 lost per year due to downtime.

How we went further

Our superior nozzle ring coating is designed to maintain an optimal flow of exhaust gases for longer. Reducing turbo washing from around 60 times a year to just 10 slashes downtime and increases efficiency and productivity.

Results

Our coated nozzle rings are delivering major cost savings across marine and stationary applications. Based on a typical 50 hours of cleaning downtime saved every year, a dredger with a 10,000 kW engine capacity can create $175,000 in additional revenue. By the same measure, a power station working with 17,000 kW engine capacity can generate $374,000 in extra energy sales.

Key results