First, it lowers a vessel’s exposure to both carbon pricing and the risk of penalties for exceeding carbon intensity thresholds. Second, the lower fuel bill could allow operators to keep much-needed funds in reserve, as they prepare to invest in the cleaner technology or more expensive fuels they will need for the later years of the new regulatory regime.

One of those regimes, the EU Emissions Trading System (ETS), is already in effect. This year marks the first time that operators will need to monitor the CO2 emissions of ships calling at European ports, with a view to buying carbon credits to cover 40% of those emissions next year. From 2026, that number will climb to 70% of their EU reported emissions, and credits will also be needed to cover methane and nitrous oxide emissions. From 2027, ships will have to buy credits for 100% of their reported emissions within the EU. This marks the first time that ship operators have ever been subject to market-driven carbon pricing.

The picture becomes even more challenging next year, when the FuelEU Maritime regulation comes into effect. Vessels calling at European ports will need to comply with phased annual reductions in the carbon intensity of fuel used or face financial penalties. Starting with a 2% decrease in 2025 and reaching up to an 80% reduction by 2050, it is clear that operators will have to alter fuel and technology choices dramatically to achieve those significant cuts in carbon intensity. Penalties for failing to do so will be severe, at €2,400 for each unit of energy consumed above the target (with a unit equivalent to the energy contained in a single ton of very low-sulfur fuel oil).

There are a few options for reducing the risk of penalties. The most straightforward single move, burning low carbon fuels, will not be possible until these fuels are more widely available.

Lowering emissions and costs starts with engine optimization

Other options, such as energy-saving devices, come with potentially expensive installation projects or, in the case of slow steaming, operating constraints that may not suit all vessel types. For Accelleron Head of Global Sales & Marketing for Digital Solutions, Shailesh Shirsekar, there is one option that all operators should take up before considering any further measures.

“Whether you are looking to comply with the first few years of the regime with a relatively low-cost option, or simply hoping to find your vessel’s best baseline performance before making future investments, engine optimization is always the starting point,” Shirsekar explains. “The savings from optimization alone can be considerable, and when it comes to burning expensive low carbon fuels or installing costly efficiency technologies, it makes complete sense to do so with fuel consumption and spend already optimized.”

In January, Korea Marine Transport Company Ship Management reported that it had saved US$540,000 in a single year after installing Tekomar XPERT, Accelleron’s state-of-the-art digital engine optimization solution, on twelve Panamax vessels. Once those savings also result in lower emissions trading exposure and reduced risk of carbon intensity penalties under the new European regime, the full benefit of optimization becomes apparent.

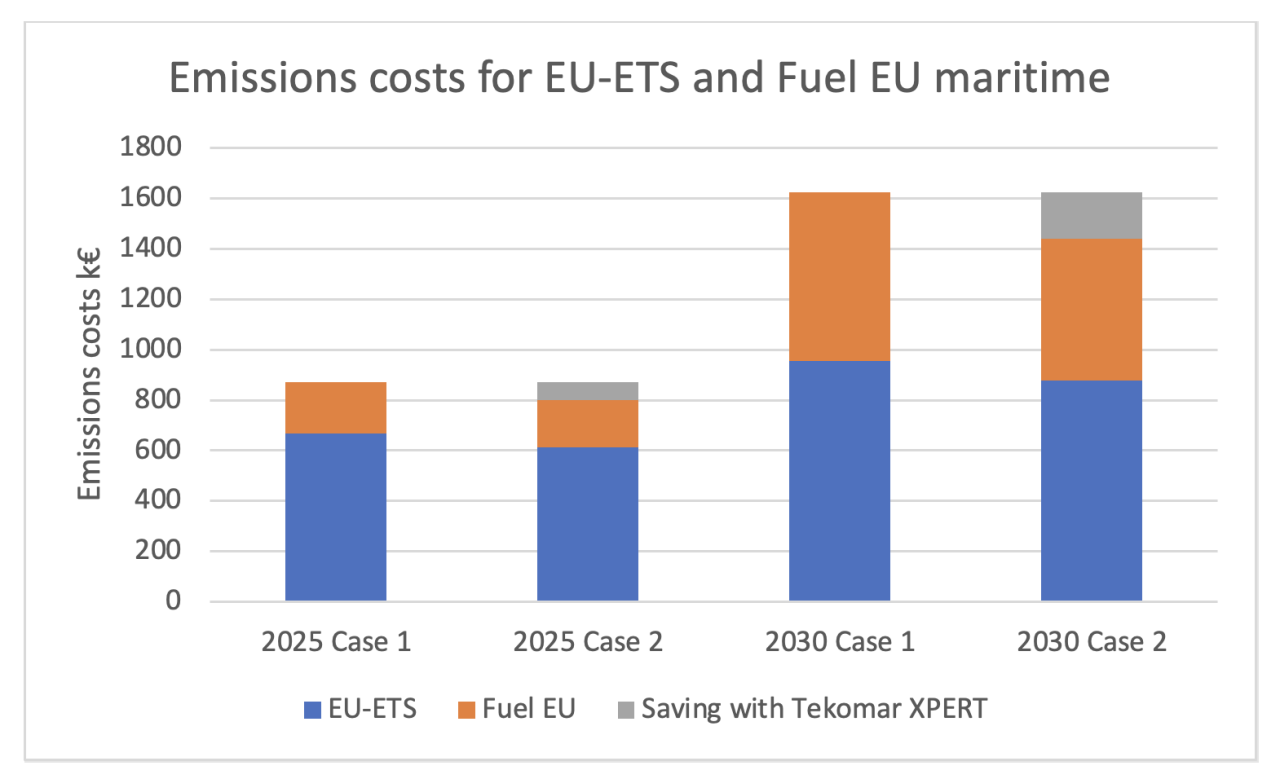

As an example, Shirsekar points to a recent case study calculated for a 37,500 DWT chemical tanker sailing intra-EU routes (and thus with 100% of emissions and fuel use covered by EU ETS and FuelEU by 20271). Simulations were run for the years 2025 to 2030 for two cases. In the first, the vessel operates as per its 2023 recorded data, using 3,500 tons of low-sulfur fuel oil and 750 tons of marine gas/diesel oil annually, In the second case, 10% less fuel is consumed by the main engine, resulting from engine performance improvements and hull and propeller cleaning recommendations made by Tekomar XPERT.

The outsized impact of digital engine insights

The resulting EU ETS and FuelEU Maritime costs show the advantages of optimization very clearly, says Shirsekar. “By applying a 10% performance optimization, the chemical tanker operator will save €72,000 in emissions costs in 2025. By 2030, performance optimization will save €183,000 a year.”

Those compliance cost savings are in addition to the fundamental 10% annual savings on the fuel bill, and their scale gives an indication of how much operating expenditure can be redirected to other efforts to make vessels more efficient. For a system that is simple to install and pays for itself in under a year, that makes installing Tekomar XPERT an obvious choice, says Shirsekar.

“Hundreds of vessels already benefit from the robust connectivity, performance transparency and data-driven improvements that Tekomar XPERT brings,” he notes. “For all those now considering their options in the face of EU ETS and FuelEU Maritime, installing it may be the easiest decision you ever have to make.”

Accelleron will be showcasing Tekomar XPERT during SMM Hamburg. Visit us at Hall A3, Booth 210 to learn how Tekomar XPERT and engine optimization can reduce your fuel and compliance costs and help accelerate your sustainability journey.

1. Excluding EUA price changes and use of onshore power supply