The International Maritime Industry (IMO) has set some challenging targets for the shipping industry, not least the need to cut greenhouse gas (GHG) emissions by 50% by 2050 compared to 2018. The industry needs to move fast, with engine manufacturers and other key technology partners seeking solutions, and it’s helping to drive innovation at an unprecedented rate.

Decarbonization targets have transformed research, which was previously dominated by traditional targets such as higher efficiency, higher power density and new engine types before the industry began to take IMO targets seriously. We’re already experiencing a completely different dynamic and a different level of spending by engine manufacturers and their partners on research and development.

There’s a huge amount of momentum, and it’s not restricted to the marine industry; we are also beginning to see a number of promising developments emerging throughout the energy market as well.

With the maritime industry responding quickly to cut emissions, however, we may also see more stringent targets introduced. After all, the IMO is expected to discuss proposals looking at more ambitious GHG emission reduction targets at the MEPC80 meeting in June.

The need for future fuels

Regardless of whether the IMO strengthens its efficiency goals, it’s clear that the maritime industry will need to embrace alternative so-called Net Zero Carbon fuels. For ocean-going vessels, this means the current propulsion system, with a low-speed main engine directly coupled to the propeller, is here to stay.

As such, the biggest challenge is that this technology must be ready and available to burn future fuels. This is where all the key technology providers, including Accelleron, need to play their part.

We’ve already seen ship owners and operators turn to a range of alternative fuels, including LNG, methanol and even hydrogen for short-haul journeys, but we’re particularly excited by the first green ammonia projects, expected to be delivered after 2025.

It is important for our industry to move forward with confidence, as this is no time for placing bets on something exotic. Given the tight timeframe, we need to get it right from the beginning – there’s not much time for testing fundamentally different routes that potentially lead nowhere.

Christoph Rofka, Accelleron’s President of Medium, Low Speed & Rail, and VP Communications at CIMAC

Christoph Rofka, Accelleron’s President of Medium, Low Speed & Rail, and VP Communications at CIMAC

What ammonia means for turbocharging

Ammonia is one of the most promising solutions, but there are also plenty of challenges that need to be solved, and the first full-scale engine tests are yet to be undertaken. We need more renewable energy sources to produce ammonia on a much larger scale, for example, along with infrastructure and bunkering solutions. In the meantime, however, we’re already starting to see a wider uptake of dual-fuel engines.

This means vessels can run on both diesel and diesel-like low carbon fuels including natural gas or regenerative fuels of biological or non-biological origin. It also means that engine concepts in the short term are likely to remain close to those already in existence, with the biggest changes from a turbocharging perspective likely to be an additional focus on efficiency and fuel consumption.

While dual-fuel solutions mark a progressive first step in the transition to more sustainable fuels, engines operating solely on ammonia are likely to differ quite a bit from today’s solutions, with very distinctive combustion characteristics likely to result in richer burning strategies to overcome ammonia’s weak flammability and ignitability characteristics.

We’re also likely to see big changes when it comes to engines running on hydrogen, although these are unlikely to play such a large role in deep-sea shipping. The high flame speed and highly ignitable nature of hydrogen combustion means engines are more likely to run an increased air to fuel ratio, resulting in higher pressure operations on the turbocharger compared to current solutions.

The need to adapt fast

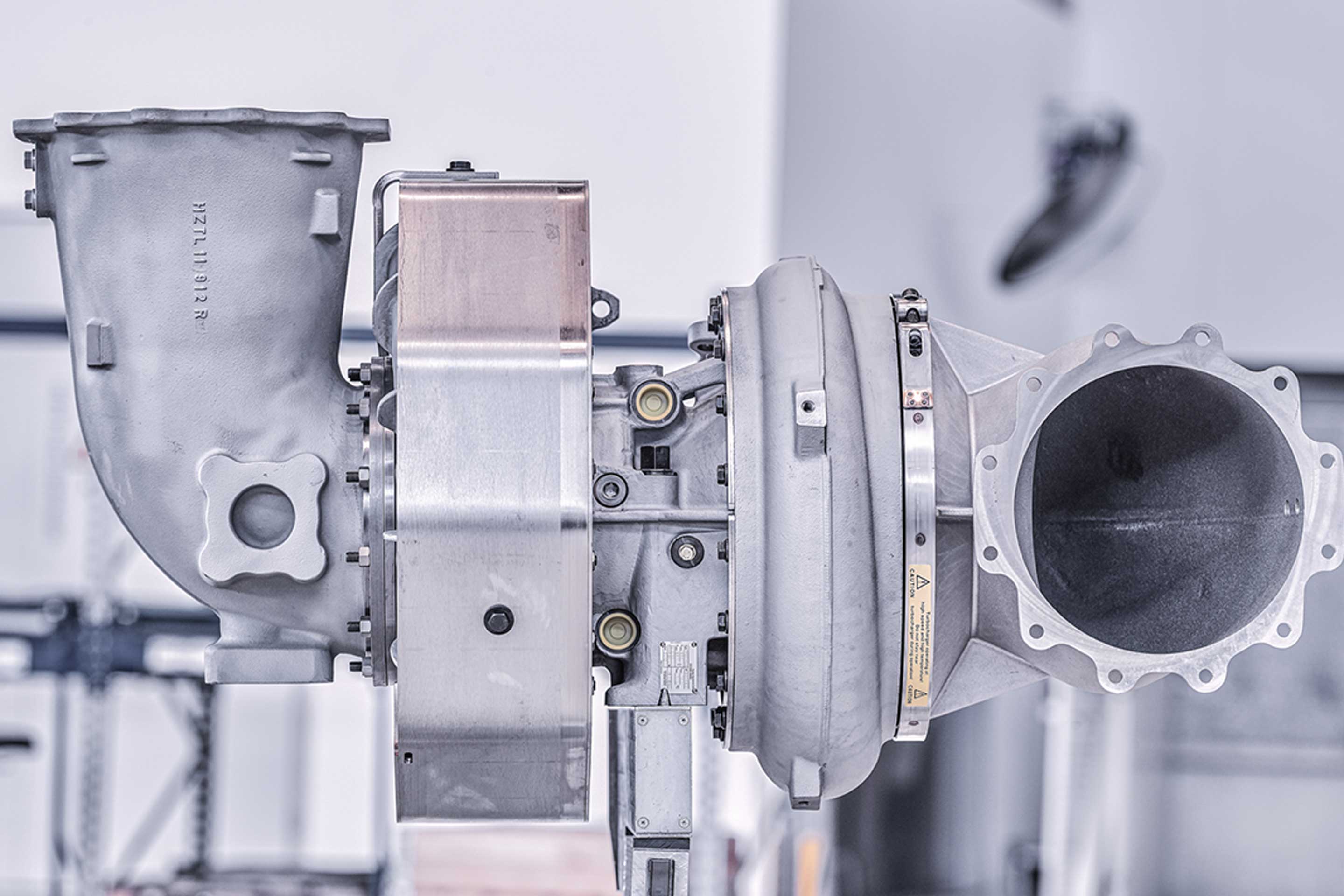

With big changes on the horizon, Accelleron has fundamentally evolved, and we are committed to helping accelerate industry transformation towards a decarbonized world. That means being able to deliver new turbocharger solutions within a highly compressed timeframe, helping to drive engine and technology development as a result.

A modular design means component-level upgrades can be introduced in turbine or compressor stages as technology advances, without having to replace entire turbocharging solutions. We are also examining the possibility of a design platform that enables the core of our turbochargers to be replaced during port stays, meaning our customers can benefit from the latest technology in shorter timeframes.

We are working with industry partners early on in the development cycle, which is a logical response in a fast-evolving market. We are progressing and learning as we go, and we must adapt quickly. It’s a completely different philosophy for us, but it’s strategically key that we position ourselves on the most relevant future fuel engine platform developments. We’re not only looking to provide the best possible hardware for testing, but we’re also able to support with engine performance simulation.

Such overall integration is an area where Accelleron can make a key difference, and our new hardware together with digital and our service capabilities amount to a service offering that is a comprehensive step change, if not an evolutionary leap.

One thing will always remain the same however, and that’s the fact we want to be the turbocharger maker with the highest efficiency levels. That will never change.

Christoph originally discussed decarbonization and the changes affecting the wider maritime industry with The Motorship’s Nick Edstrom. Read the full interview here.