Increased engine and fuel efficiency is indisputably good for business, but also an increasing necessity as environmental regulations and requirements take hold. But how can ship owner-operators push their fleets harder?

We’ve already seen innovations within the maritime industry to help tackle emissions and fuel efficiency, and this week ABB Turbocharging announced a partnership with Hyundai Global Service (HGS) to offer an engine part-load optimization (EPLO) service for shipowners seeking to cut emissions in line with the International Maritime Organization’s (IMO) requirements. This is just one of the ways that that the maritime industry can work towards the World Economic Forum’s goal of #ZeroEmissionShipping by 2050.

Boosting engine efficiency – the maximum energy for the minimum cost – is, and will always be, a key goal for ship owners and operators. Fuel costs – the major operating expense in marine transport – have risen again in 2021, to pre-pandemic prices. Getting every joule from your juice is a commercial imperative. This is set to continue: future fuels, like ammonia or methanol are in shorter supply than diesel oil, and will be for some years to come.

Aside from commercial motivations, consuming less fuel produces fewer CO2 emissions. This is not only an undisputed necessity in terms of fighting the climate crisis, but also a requirement under multiple regional and international regulations, regulations that will only become more and more stringent in coming years. Notably, the Energy Efficiency Design Index for Existing Ships (EEXI) will make Engine Power Limitation (EPL) a key ingredient in reducing greenhouse gas (GHG) emissions.

Increasingly, too, customers in marine transit — notably, consumer brands like Nike and IKEA — are declaring commitments to lowering their environmental impacts and decarbonizing their supply chain, with an inevitable impact on their logistics partners.

So, what are the immediate next steps for owner-operators? Here are the basics of three approaches.

Engine derating

Slow steaming, or the reduction of marine vessels’ sailing speed, is a well-established method to reduce both fuel consumption and emissions. A speed reduction of 10% might result in a 10-15% decrease in NOx emissions. It can also result in fuel savings in the region of 20%, with CO2 emissions also reduced by 20%. Thanks to this relationship between fuel consumption, emissions and speed, relatively low levels of speed reduction can pay off handsomely.

Slow steaming may seem like a simple and effective solution. But there are complications. Any ship’s main engine is optimised to perform best within very specific parameters – including the speed at which it operates, often between 75 and 85% of its maximum power. Operating the engine outside these parameters will reduce its efficiency, thus reducing the positive benefits of slow steaming. Also, operating at lower speeds can increase wear and tear, the risk of failures and increase maintenance costs.

To reap the full benefits of slow steaming, temporary or permanent adjustments to the engine, such as the upgrades made by tanker operator Odfjell, may well be required. Such measures – which can take numerous forms, adapted to the technical and commercial requirements of the owner-operator – are applicable to most engine types, will increase reliability and dramatically reduce fuel consumption and are especially recommended when the reduction of NOx emissions is a priority.

Turbocharger cut-out

The work to ensure a vessel’s propulsion system is better optimised for slow steaming will inevitably also include attention to the turbochargers. Just like the engine, turbochargers are tuned to perform most effectively under particular operating conditions, and – once again – simply cutting the throttle won’t yield the maximum possible efficiency gains unless the operation of turbochargers is optimized against the new conditions created by slow steaming.

Notably, the reduction in engine power settings might mean that fewer turbochargers need to be operational during slow steaming – and this will actually increase fuel-efficiency. By installing a turbocharger cut-out system, the engine operator can disable one of its turbochargers during low load operations. This, in turn, increases the efficiency of the remaining turbocharger(s), by returning their operating levels to within their normal parameters for optimum performance. Like engine derating, turbocharger cut-outs improve fuel efficiency during slow steaming – by 6-10 g/kWh – and also improves the reliability of the turbocharger by restoring its intended operating conditions, thus reducing the incidence of smoke and deposits, as well as wear and tear.

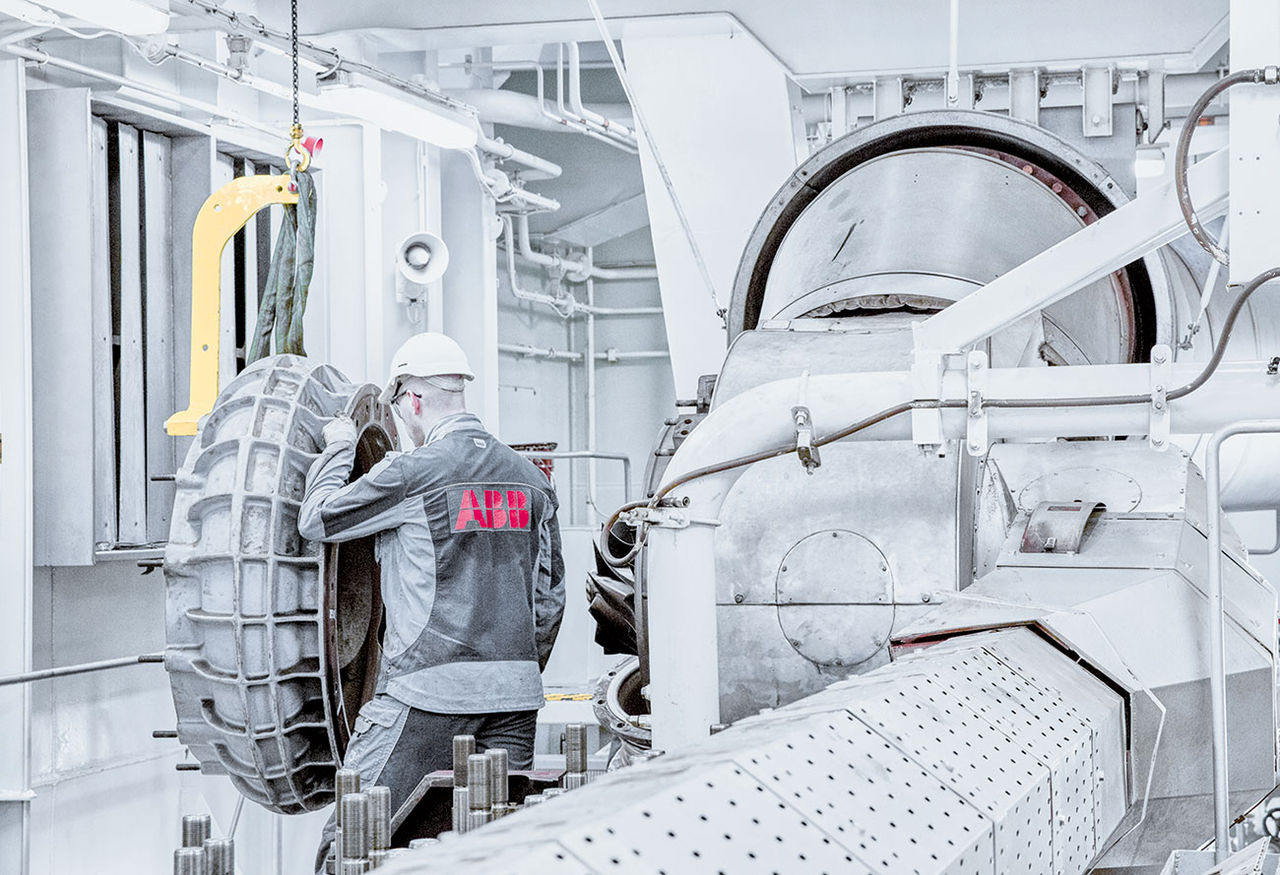

This approach has the added benefit of simplifying IMO certification procedures, but – as should be clear – will only be applicable to engines with two or more turbochargers. ABB service engineers can advise on the best routes for every vessel.

Turbocharger upgrades

An alternative or complement to engine changes is to consider upgrading or replacing your existing turbocharger. Turbocharger design and performance have continually been refined and improved over the decades, with meaningful updates introduced to new turbochargers on a very regular basis. At the same time, installed components wear out over time, leading to lessening efficiency and a greater chance of failure. Over time, turbochargers need to be replaced.

But fortunately, it’s now possible to give an older model a new lease of life. ABB turbocharger upgrade program replaces the internal parts of turbochargers — the parts most subject to wear and tear — with the latest iterations of those components. This operation not only restores previous performance, but beats it, through the improvements in design. These component upgrades are already available for some of the most popular medium speed models in the market, including the TPL76-C, TPL73-A and TPL-69-A, TPL67-C and TPL77-A, with more models soon to be added to the offering.

The impact can be considerable, especially alongside matching engine upgrades. With a 17MW engine and a TPL76-C turbocharger, savings of 526.5 tons of fuel have been achieved over a year. And reduced fuel consumption not only lowers the fuel bill but also reduces emissions, contributing towards a greener future. As an added benefit, replacing these vital components will increase the turbocharger’s lifetime. Further, the recommended exchange interval of the rotating parts can be extended from 50,000 to 75,000 running hours.

These are just three ways ship owner-operators are increasing their profitability and moving towards a low/no carbon future already. Maximum efficiency will always be a journey, rather than a destination, though, because the possibilities are continually evolving to offer more ways to save fuel and cut emissions. But the great news is that improvements are always possible, and lower cost options are within everyone’s reach.