Vessel owners and operators can enjoy significant long-term economic benefits thanks to FiTS2. The innovative turbocharger technology allows maximum fuel savings for two-stroke engines at part and low load, while maintaining the flexibility to go to full output immediately.

FiTS2 stands for Flexible integrated Turbocharger System for two-stroke engines. FiTS2 allows fast and flexible adaptation of an engine’s output characteristics to new load profiles – for example, to cope with changes in a vessel’s route – quickly and whenever needed. In addition, the system enables fuel savings of up to 8 grams per kWh (3 – 5 percent) compared with fuel consumption levels typically achievable with conventional turbocharging systems on low-speed diesel engines.

FiTS2 therefore represents a vital innovation step for the marine industry that brings clear added value to both engine builders and engine operators alike. Depending on the price of fuel and the load profile to be met by the engine, the fuel saving over ten years can amount to $500,000 USD for a very large crude carrier (VLCC) and well over $1 million USD for a container vessel. The return on investment from equipping an engine with FiTS2 is thus clearly apparent. With such substantial fuel cost saving potential, the investment in FiTS2 on a container vessel will be amortized in less than three years.

FiTS2 brings benefits at any fuel price

During periods of very high fuel prices and very low demand for transportation in the recent past, vessels were run at reduced speed, to benefit from the low fuel consumption at the resulting lower engine loads – “slow steaming”. Often these low loads were outside the engine’s design parameters and lower consumption was bought at the price of higher maintenance, repair and overhaul.

Even though fuel prices are currently at relatively low levels – so are freight rates –, there is still an understandable desire to reduce fuel consumption as far as possible. With FiTS2, the operator can rapidly – and safely – adapt his engine’s performance to suit his current needs; slow steaming to save fuel and faster vessel speeds whenever required.

Looking at the bigger picture, FiTS2 also has the potential to be a very useful factor in helping vessel designers achieve the progressive improvements in actual vessel operation efficiency – and hence lower greenhouse gas emissions – required under the International Maritime Organization’s Energy Efficiency Operational Indicator (EEOI) and European Union MRV regulation.

Consequently, the focus on part load and low load operation seems to be inevitable, making FiTS2 a perfect solution for the further lowering of costs, and even more so in the event of fuel prices going up – as they surely will at some point.

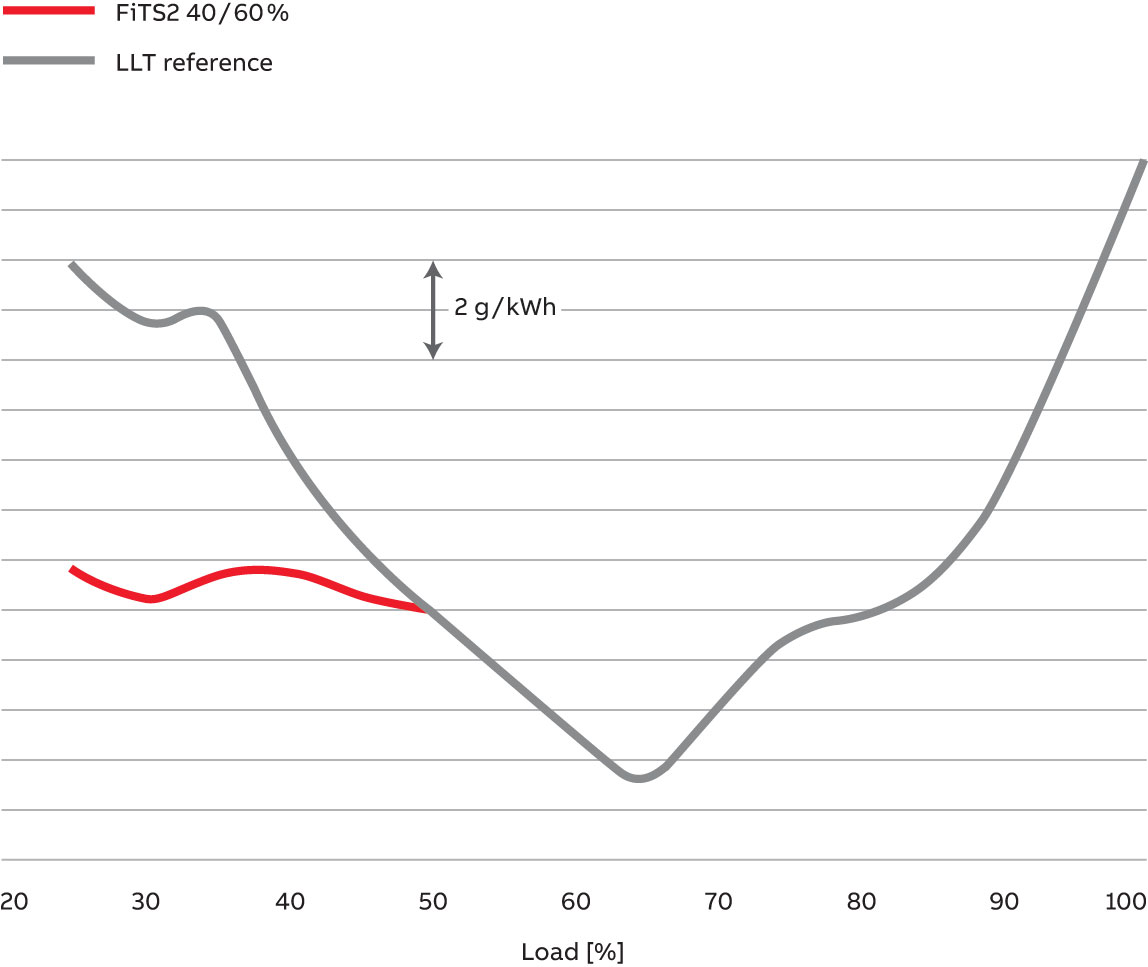

The diagram shows the fuel saving potential of FiTS2 in comparison with a low load tuning solution with exhaust waste gate (LLT)

The diagram shows the fuel saving potential of FiTS2 in comparison with a low load tuning solution with exhaust waste gate (LLT)

Turbocharging system tuned to customer needs

FiTS2 is the result of continuous ABB innovation, aiming to perfectly match the market needs of economy and flexibility simultaneously. FiTS2 denotes a complete, integrated turbocharging system (see also: FiTS2 – how it works). It consists of sequential turbochargers of different size, specifications and wide compressor maps. As the name suggests, in sequential turbocharging, two or more turbochargers operate in sequence to complement each other’s air delivery at different engine loads. The turbochargers are controlled by a specially developed FiTS2 tuning software, combined with dedicated, flow optimized valves, which can operate under full load.

Development partnership with WinGD

To develop FiTS2, ABB entered into a close cooperation with low-speed two-stroke engine designer Winterthur Gas & Diesel Ltd. (WinGD). ABB delivered the turbochargers, the valves and the control system, while WinGD carried out the special tuning on its engines. Like ABB, WinGD is convinced of the benefits FiTS2 delivers. Dominik Schneiter, Vice President, Research & Development at WinGD: “In the long lasting and successful strategic cooperation with ABB, WinGD has made several major advancements in engine optimization, such as optimized two-stroke Miller tunings with high pressure ratios and part load optimized waste gate applications. This intense cooperation continues and has now provided the jointly proposed ISTC tuning for FiTS2 turbocharging, which will offer ship operators further flexibility in lowering fuel consumption and improving the CO₂ footprint of their ships, particular at low and mid load operation.”