Variable Turbine Geometry (VTG) turbocharging technology, introduced on Indian Railways one year ago, strongly supports the company in its efforts to meet power, fuel and emission targets.

With ABB’s latest flexible solution transferred to the TPR 61 frame size, Indian Railways (IR) were encouraged by the benefits of Variable Turbine Geometry (VTG) to move from fixed geometry turbochargers to VTG technology-based turbocharging. In commercial operation for more than one year now, IR’s VTG turbocharger is performing excellently on locomotive no. 14818R at Diesel Shed Pune.

The VTG turbocharger controls exhaust gas flow by using movable nozzle ring vanes to maintain the optimum boost pressure and air-fuel ratio commensurate with every engine / locomotive operating point on a real-time basis. It allows overall optimization of the engine system by adding flexibility in operation at higher altitudes and a wide range of ambient temperature variations without any derating. It also helps to improve combustion efficiencies, especially in the mid-load range.

VTG test results

Test results with the VTG technology-based ABB turbocharger at the Research Designs & Standards Organisation (RDSO) test bed* proved a 2.74 percent fuel saving on IR passenger duty cycle and a 2.95 percent fuel saving on the IR freight duty cycle against an assured fuel saving of 2 percent.

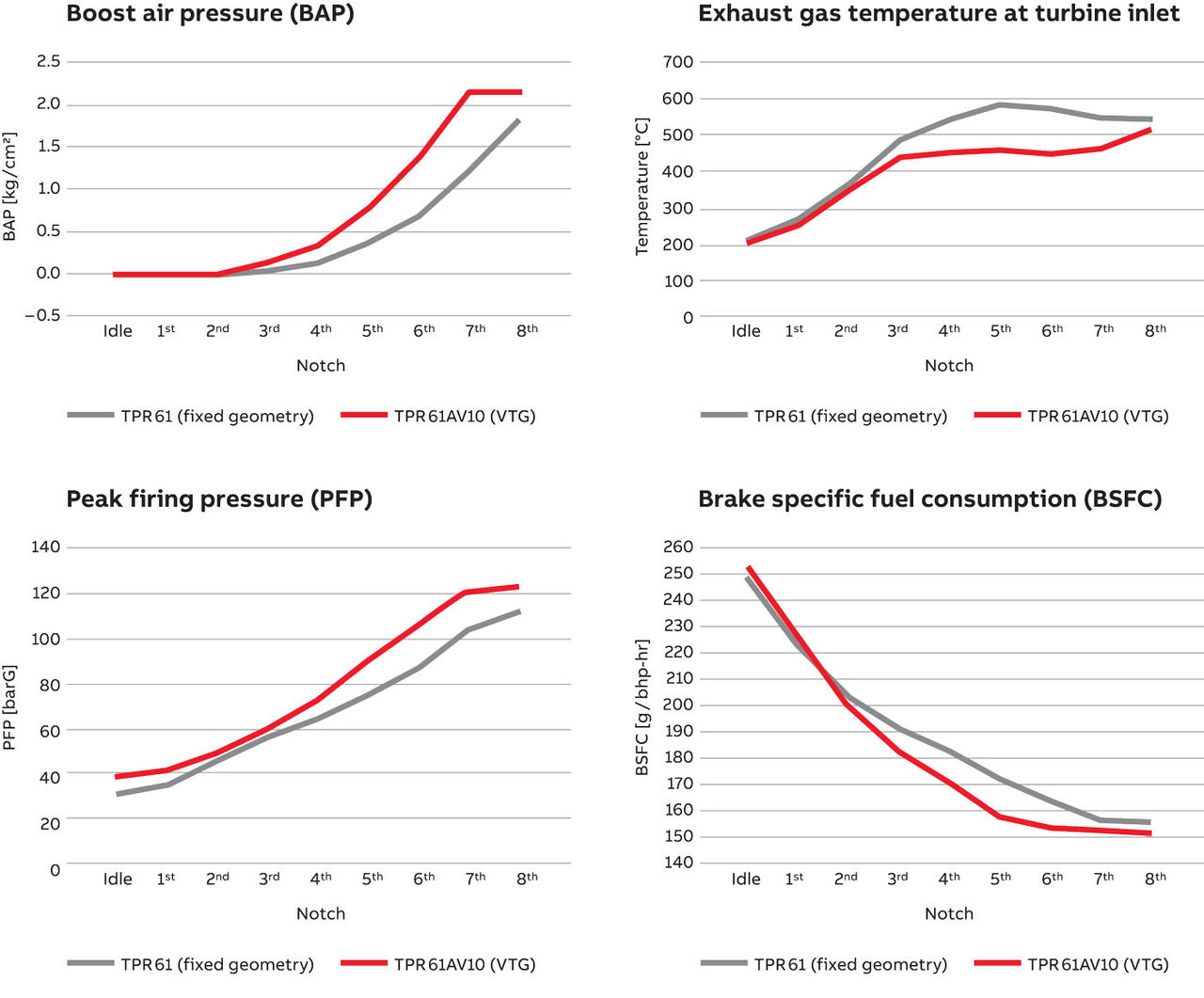

Glimpses of key performance indicators on a test bed

Glimpses of key performance indicators on a test bed

Proven benefits aside of the substantial fuel saving

- Improved Boost Air Pressure (BAP), especially at part load.

- Reduction in exhaust gas temperature at turbine inlet found to be lower, ranging from 80 °C to 120 °C, particularly during mid-load engine operation, thus cutting temperature peaks and thermal load of engine components.

- Peak Firing Pressure (PFP) within prescribed limit. Carbon monoxides (CO) 60.86 percent lower for IR passenger duty cycle and 58.87 percent for IR freight duty cycle.

- Particulate matter found to be 51.28 percent lower than baseline test with fixed geometry turbocharger.

Overall, ABB’s VTG technology-based turbocharger TPR 61AV10 meets the recent efficiency and performance requirements of Indian Railway’s DLW built 16 cylinder 251B engine with flying colors.

Indian Railways and ABB Turbocharging addressing progress jointly

ABB Turbocharging has had a strong association with Indian Railways for more than 35 years, having partnered with IR on various diesel locomotive upgradation programs since 1985. ABB has provided efficient solutions for almost all classes of locomotives in the range of 750 hp (VTR 250), 1350 hp (VTC 214), 2300 hp (VTC 304), 2600 hp (VTC 304), 3100 hp (VTC 304 and TPR 61) and 3300 / 3600 hp (TPR 61).

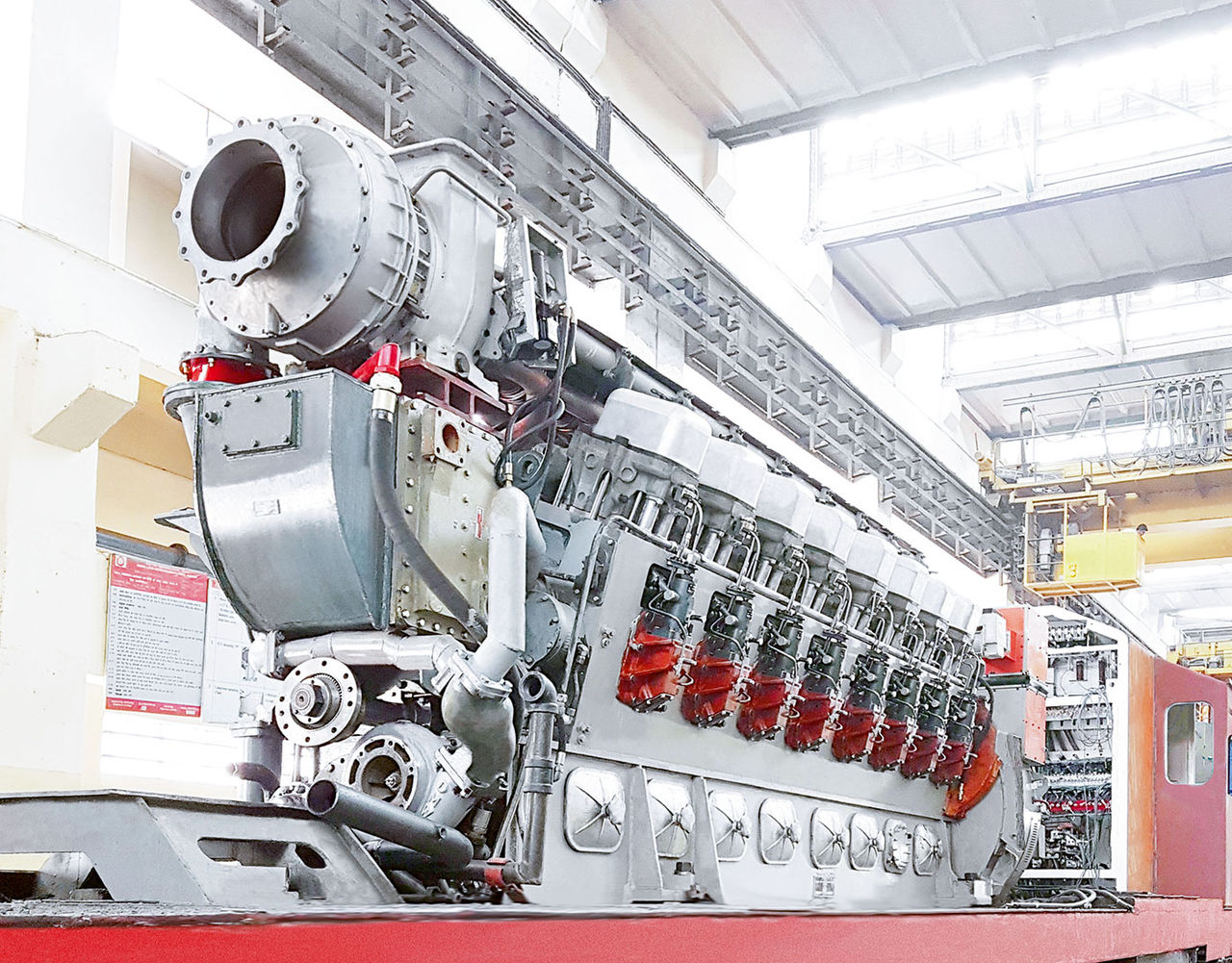

Since their introduction in 2001, TPR 61 turbochargers have been supplied by ABB Turbocharging from its manufacturing facility based at Maneja, Vadodara, for DLW built 3100 / 3300 / 3600 hp diesel engine based locomotives, which represent approximately half of the total diesel locomotive fleet of Indian Railways. Currently, more than 2400 TPR 61 turbochargers are in operation on DLW built 16 cylinder 3100 / 3300 hp diesel locomotives at Indian Railways.

Greater demands are being placed today on railway application engines in India. Increasing fuel prices and stricter emission regulations call for flexible and reliable solutions. In line with IR’s fuel saving initiative, ABB Turbocharging has participated in the development of efficient solutions which have helped Indian Railways to ensure all of the three prime benefits of turbocharging are achieved, i. e. an increase in power, fuel saving and / or a reduction in emissions. ABB Turbocharging solutions not only demonstrate an increase in overall diesel engine efficiency but also ensure the safe and reliable operation of diesel

locomotives.

ABB’s supplementary solution aimed at reducing NOx emissions – the Miller technology based ABB turbocharger – is currently being tested and will also pave the way to further emission reduction benefits. Ultimately, the combination of VTG and Miller technology will enable even greater operational benefits.

Commissioning

After testing, the VTG Technology based ABB turbocharger was commissioned on WDG3A diesel locomotive no. 14818R at IR’s manufacturing unit Diesel Loco Modernisation Works (DMW), Patiala. This was carried out within the existing envelope constraint, ensuring proper matching with existing mating assemblies of the engine / locomotive. Necessary cabling and mounting of the electronic control module were performed jointly at a designated place. After fitting, the locomotive was flagged-off for field operations on May 28, 2017 after its first track run on the 100 km loop.

Inspired by success

VTG has successfully proved its significant benefits on the RDSO test bed not only due to the approximately 3 percent reduction in IR duty cycle fuel consumption but also by exhibiting reduced thermal loading and exhaust gas temperatures with a reduction in emission parameters. And to these must be added the other benefits of VTG: flexibility in operation, delivery of the full power of the locomotives at varying ambient temperatures and at any altitude across the varied Indian terrain. Being proven in field operation is the icing on the cake.

Inspired by the success on the RDSO test bed and during field trials at Diesel Shed Pune, Indian Railways is now considering VTG technology based turbochargers for further implementation on DLW built 16 cylinder 3100 / 3300 hp locomotives as an upgrade solution that will realize all the benefits proven on locomotive no. 14818R.

About Indian Railways

Indian Railways (IR) is India’s national railway system operated by the Ministry of Railways. It manages the fourth largest railway network in the world by size, with 121,407 kilometers (75,439 miles) of total track over a 67,368 kilometers (41,861 miles) route length. 49 percent of the routes are electrified, while 33 percent of them are double or multitracked.

IR runs more than 13,000 passenger trains daily, on both long-distance and suburban routes, from 7,349 stations across India. In the freight segment, IR runs more than 9,200 trains daily. In the financial year ended in March 2018, IR carried a total of 8.26 billion passengers and transported 1.16 billion tons of freight annually. As of March 2017, IR’s rolling stock included a total of 11,452 locomotives, of which almost 50 percent are diesel locomotives.