In an exciting opening day at the Motorship Propulsion & Future Fuels Conference, where we also looked into the significance of data in achieving sustainable performance, Accelleron’s Simone Bernasconi, Head of Global Product Line Upgrades, discussed how turbocharging solutions can support the decarbonization journey.

Simone’s presentation highlighted how easy-to-implement turbocharger technology can play an important role in reducing the CO2 footprint of existing installations. Wide market adoption is key to achieving significant impact, Simone points out, and combining greater efficiency with a sound business case will be vital to maintaining a competitive edge in a low-carbon world.

Maximizing the fuel efficiency of merchant vessels has always been a key goal of the shipping industry, says Simone. Fuel costs are the major operating expense in marine transport and have recently seen all-time high values. The need for decarbonization is also gaining momentum at an incredible pace, with stringent targets from the IMO further enhancing the need to improve transport efficiency.

Decarbonization approaches for the maritime industry

Despite the lowest specific CO2 emission for transported goods per weight and distance, and achieving solid specific emission reductions in the last decades, the maritime industry doesn’t have a clean image. The global perception is rather negative, with maritime transportation often seen as dirty and even non-compliant.

The expectation on our industry is high, and we – as the maritime industry – are expected to make the difference in the future.

Decarbonization needs to be implemented throughout the whole value chain to deliver a holistic approach, considering overall CO2 emissions and environmental impact. Drawing the system boundary on the vessel and focusing only on downstream emissions stemming from its chimney (tank-to-wake) is not sufficient. The origin of fuel and grey energy involved (well-to-wake) need to be considered to avoid distortion and in the worst case, a global increase of CO2 emissions despite clean shipping on paper. Such life-cycle considerations, although highly complex, are paramount to a sound decarbonization journey.

Decarbonization targets are ambitious and consequently, to achieve a perceptible global impact, solutions for decarbonization and efficiency improvements must be widely adopted. Flagship projects are required for showcasing new technology, but their direct global impact is marginal. It is pivotal to success that today’s technology demonstrations become tomorrow’s widely adopted standards. This may be achieved by considering global availability as well as affordability from the very early conception phase of proposed technology improvements.

Long term solutions (net-zero transportation)

Net-zero maritime transportation is already possible. Fully electrified short-range ferries and even medium-range ferries are possible, provided the electricity itself has a net-zero carbon footprint. In fact, the first installations of short-range ferries have been already in operation for a few years. The technology is not suited to long-range transportation, however. A container ship sailing from Asia to Europe with a one-month travel time would need as many as 100,000 tons of batteries on board, consuming 60% of the freight capacity.

A net zero carbon footprint can also be achieved through the use of sustainable fuel including Biofuels or fuels generated from renewable energy sources such as solar, wind and hydro. From a vessel and engine technological perspective, a full transition to net-zero emission vessels is possible in less than 10 years. A major engine OEM has already committed to the availability of ammonia engines from 2025, for example, and pilot initiatives from companies such as Maersk and AIDA with sustainable fuel are multiplying.

Yet global transition will nonetheless take several decades to be implemented. The biggest challenge to overcome is the global availability and distribution of net-zero carbon fuels. This is going to take decades to implement and is not directly in the hands of the shipping industry itself. There will also be fierce competition for sustainable energy between industries at local and global level, onshore and offshore, including electricity, heating, private transportation, aviation, construction and more.

Short and medium term solutions

Presently, we are at the beginning of the carbon transition journey. While the target and ambition are known, the exact means of implementation are widely unknown, and there will be many paths towards the common target. It is certain that during the decades of carbon transition a vast diversity of technologies will emerge which cater to incremental CO2 footprint improvements. There won’t be a one-size-fits-all solution and it’s most likely a single solution will not do the job. A sound combination of multiple incremental improvements is key to making the existing fleet fit for the decarbonization journey.

Although the IC engine remains a key solution in the short and medium term, internal combustion is at the heart of emissions related to the maritime industry, with CO2 released during the oxidation of current hydrocarbon fuels when converting chemical to mechanical energy. Future fuels, such as methanol, ammonium or hydrogen will enable a global net-zero CO2 balance when available, but we’re not there yet.

« Future fuels, such as methanol, ammonium or hydrogen will enable a global net-zero CO2 balance when available, but we’re not there yet »

Simone Bernasconi, Head of Global Product Line Upgrades, Accelleron

How turbocharging can help

The turbocharging system is a key component of the marine engine. Through its direct interaction with the engine, a modern turbocharger with higher efficiency has a leverage on emissions, directly lowering specific fuel consumption and hence CO2 emissions, through improved overall system efficiency, and also enabling new engine tuning and concepts for even higher reduction potential.

Maritime assets have a lifetime spanning several decades, from 15 to 30 or more years depending on the vessel type. Over its lifetime, marine equipment requires servicing to ensure acceptable reliability, operational safety, and energy efficiency. There are two main service approaches when it comes to servicing marine equipment, although thanks to Accelleron, it’s also possible to get the benefits of both.

Often, when components need to be repaired or replaced, the conventional service approach is to install new like-for-like equipment, featuring the same older design and technology that was available when the vessel was delivered. Although easier and cheaper to implement, this traditional service concept is no longer sufficient.

Upgrades provide an alternative approach. Older equipment is removed from the vessel and replaced by newer components with a more recent design. Benefits include the latest technology developments in efficiency, ease of service and spare part availability, but changing equipment to newer versions often requires in-depth adaptations, increasing the technical complexity, project management effort and downtime. To achieve wide adoption of upgrades globally, financial sustainability needs to be further improved, and component upgrades promise the necessary simplicity with benefits.

Accelleron turbocharger upgrades

Accelleron turbocharger upgrades

The best of both worlds

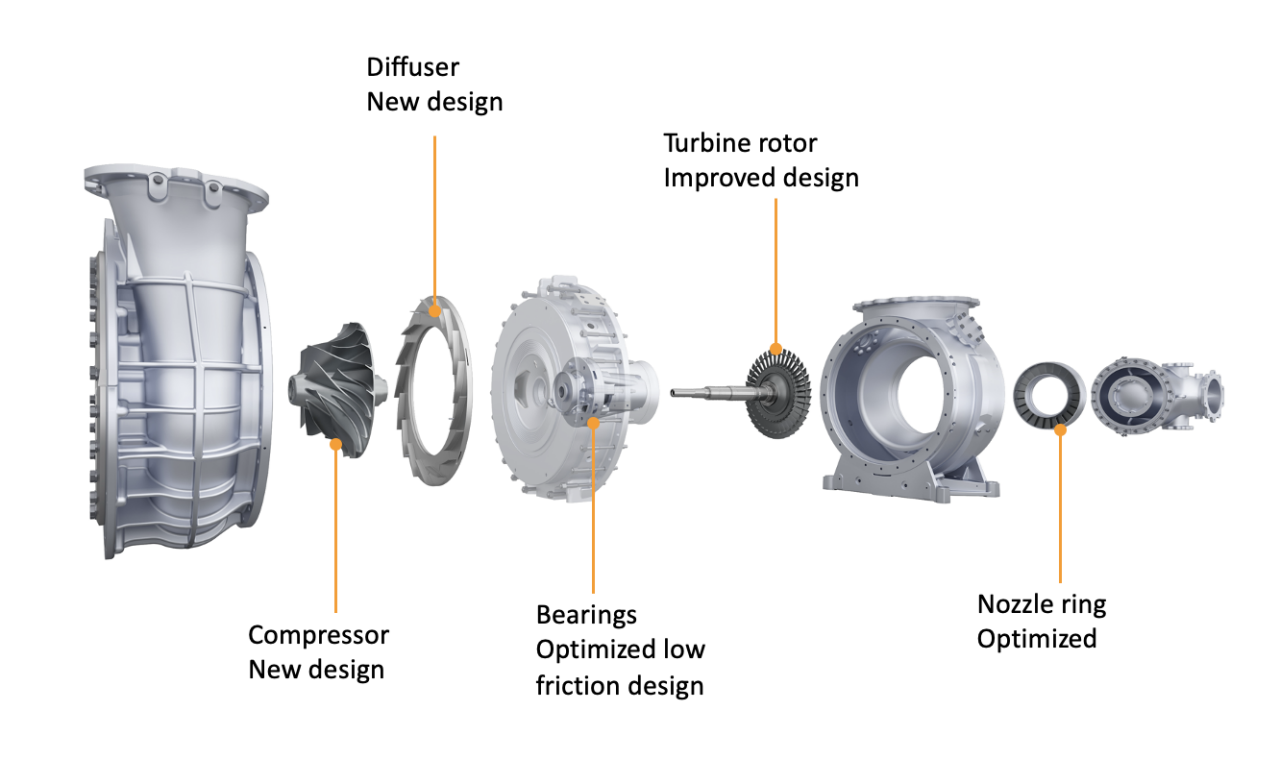

The turbocharger component upgrade is based on a simple concept:

- The latest know-how in design and materials from the newest turbocharger generation is modified to fit into older turbocharger equipment.

- Only the performance relevant components are replaced by new upgrades, while the turbocharger casings and all interfaces to the engine remain untouched.

The component upgrade approach requires a dedicated development, qualification and verification effort by equipment OEMs, but provides a great alternative to the standard servicing, helping owners and operators to improve the CO2 footprint and competitiveness of their vessels, without interfering with the already-scheduled maintenance scheme.

In conclusion

Internal combustion engines remain at the core of emissions generation for the shipping industry, and measures to reduce their environmental impact can’t be removed from the global sustainability equation. As such, they must be carefully evaluated.

Turbocharger upgrades can be integrated into the regular maintenance scheme of a turbocharger, promising to reduce direct CO2 emissions onboard the vessel through lower fuel consumption, along with indirect CO2 emissions by increasing the lifetime of key components.

Simone’s white paper provides practical examples of such upgrades, highlighting the difference that particular products and upgrades can make, along with looking at the key to enabling wider adoption. Interested in finding out more? You can read Simone’s full white paper here.