The International Council on Combustion Engines, CIMAC, holds a major international congress and exhibition every three years. It gives experts the opportunity to present the latest technology and debate the industry’s most important issues, and ABB Turbocharging was at this year’s event in Vancouver, with Paolo Tremuli, senior application manager, presenting the benefits of Power2.

Power2 is about to celebrate its 10th year of commercial availability. ABB’s two-stage turbocharging concept may be 10 years old, but the need to increase efficiency, lower emissions and reduce operating costs means that Power2 is more relevant than ever.

During the past decade, Power2 has worked alongside some of the world’s most efficient four-stroke diesel engines, has served on the world’s most advanced icebreaker, and a new frame size has enabled it to work with a larger spectrum of main and auxiliary engines.

Affordable CAPEX costs

Perhaps surprisingly, the initial cost of doubling the number of turbochargers your engine uses with Power2 is lower than you may anticipate.

“The engine without the turbocharging systems is actually a little less expensive than a single-stage design, because we can reduce the number of cylinders,” Tremuli explains. “Power2 increases the engine power density, therefore the engine can be smaller for the same output.”

“Of course, there’s a slight cost increase on the turbocharging side of things,” adds Tremuli, “as we have two turbos, one additional air cooler and more pipework, but you also have to remember that the second high-pressure turbo is also much smaller, and we have reduced the size of the larger turbo.”

As a result, the overall cost of installation for Power2 isn’t actually that expensive, with Power2 more than able to pay for itself through lower fuel bills, increased uptime and as the enabler for lower emissions.

Lower OPEX costs

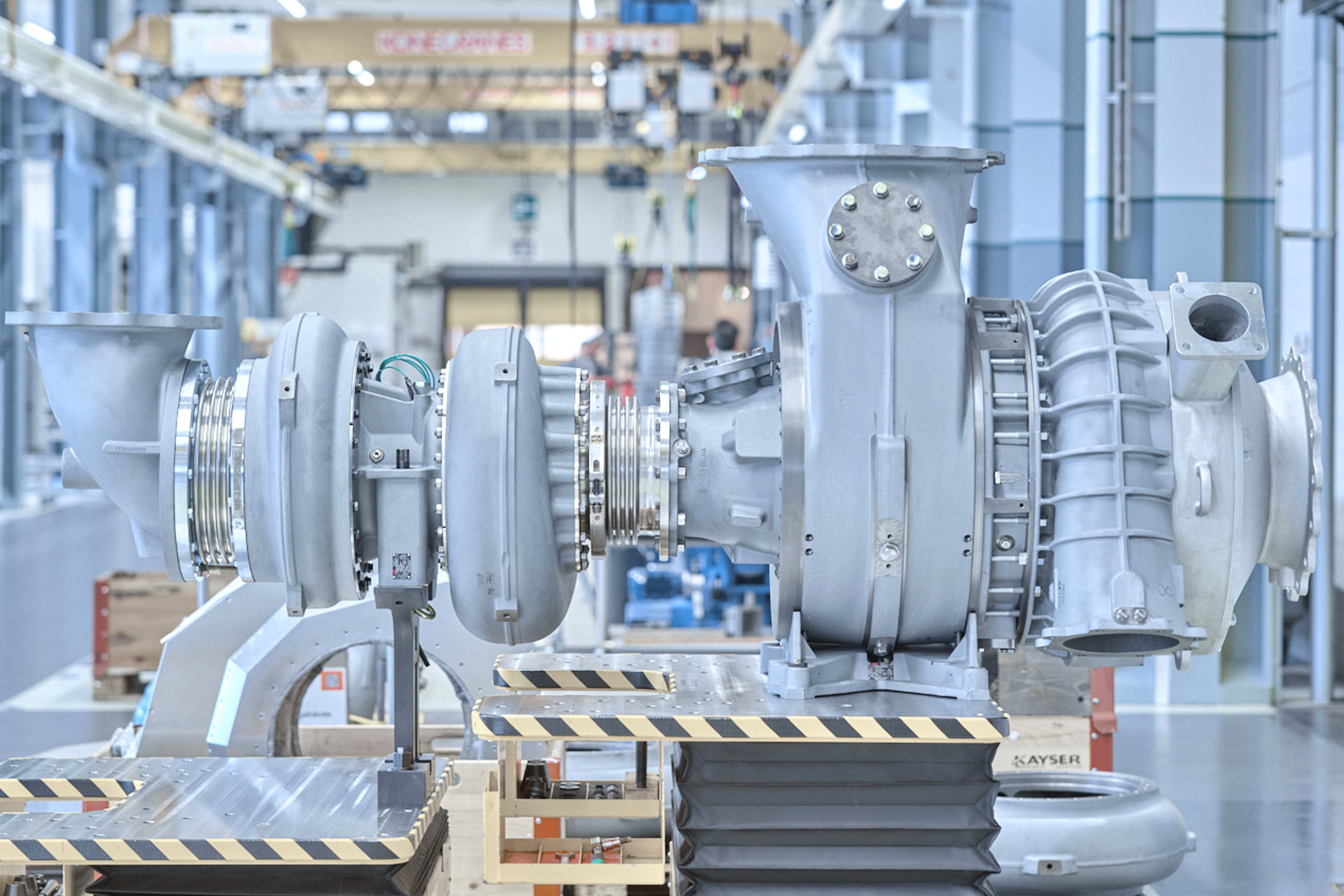

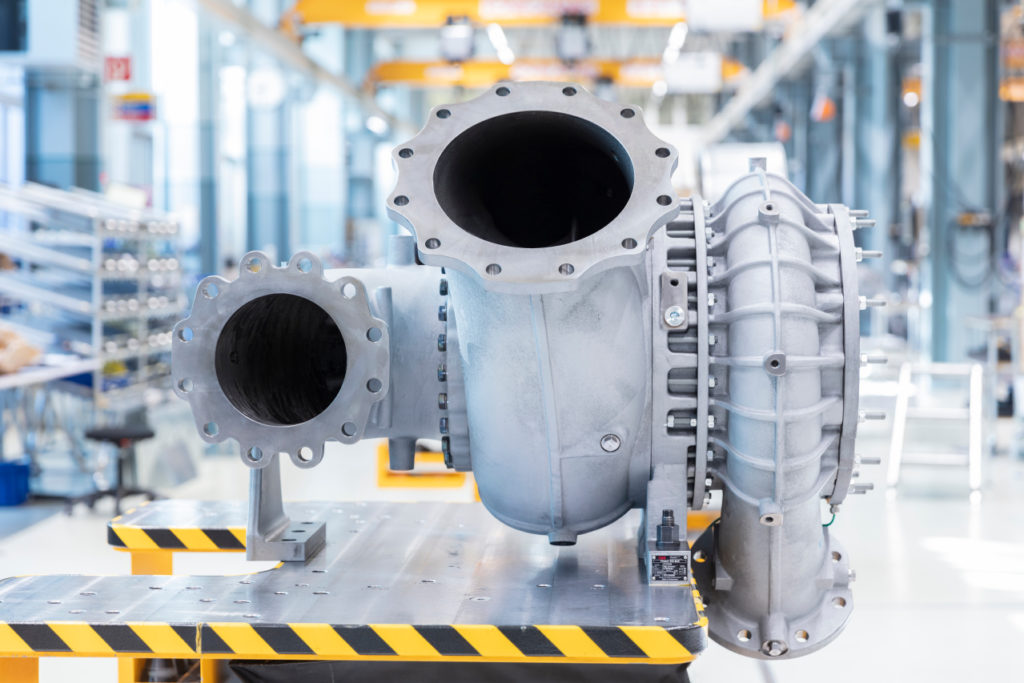

Power2 employs a main low-pressure turbocharger and a smaller, high-pressure turbocharger in place of a single unit, raising turbocharging efficiency from 65 percent to above 75 percent, supporting a pressure ratio of up to 12 and enabling the usage of Miller timing to provide increased power density. It’s even flexible when it comes to fuel, supporting the use of all fuel type and all grades, from gas to heavy fuel oils, making it possible for operators to use the fuel best-suited to their requirements.

The benefits are easy to see, with Power2 saving operators over five percent on fuel costs alone – with a 10Mw engine, that’s around 2.5 tons of fuel in 24 hours’ operation. The flexibility offered by ABB Turbocharging’s solution enables it to deliver the correct amount of air for a given Miller setting, sitting below the limit for emissions without impacting negatively on fuel consumption.

And because it’s more efficient than a single-stage turbo, Power2 also places lower thermal loads on an engine, keeping temperatures down and allowing manufacturers to opt for more affordable materials when building their engines. The increased compression ratio extends to operating altitudes. Power2 can deliver more air at higher altitudes and temperatures, enabling engines to operate at the same power, while a single-stage solution would be required to de-rate its output.

More efficient servicing

Tremuli highlights Power2’s ease of service as a key area where owners, operators and engineers can benefit, and this is because of Power2’s more efficient design. There are six different stages to removing a traditional compressor and turbine cartridge, for example, including the removal of the turbo’s air inlet, insulation, outlet flange connection, compressor casing and oil connections in order to access the cartridge. Power2 cuts the same process down to just two stages, proving that two turbochargers don’t necessarily need to be more complex.

“With Power2 we have only two steps,” Tremuli explains. “We remove the air inlet so we have access to the cartridge, and we can pull it straight out without dismantling anything else. We have a custom-designed tool to make this possible, and while it required a complete redesign of the turbocharger, it makes removing the cartridge particularly easy.”

This is particularly important when it comes to power plants, where owners have contracts to supply electricity to customers. Power2’s innovative design takes 30 percent less time to overhaul, keeping that all-important downtime to a minimum.

With CAPEX-related expenditure lower than you may imagine, and the innovative design also resulting in lower operating costs, Power2 is definitely worth consideration if you want the most efficient engine. It even comes with environmental benefits, with the second turbocharger enabling owners to downsize engines for the same given performance, benefitting from up to 60 percent fewer NOx emissions as a result. Lower costs and better emissions – what’s not to like?