How digitalization drives performance from pit lane to shipping lane

F1 partnership update | Baden, Switzerland | Apr 18, 2023

On first impressions, a 798 kg Formula 1 car designed to reach speeds of 200 mph has little in common with a cargo vessel that weighs 165,000 tons and cruises at 25 knots. But that isn’t true. Both pieces of engineering genius are constantly producing data that is being gathered, analysed and applied to optimise performance.

In the hotly-contested world of Formula 1, data is king. Teams harvest vast quantities of information during a race weekend, looking at everything from engine operating parameters to pit stop times. Those best able to harness this data, using it to understand both their own machines and the competition, gain a competitive advantage. Digitalization is key to successful data use, ensuring engineers have the relevant information to hand, when they need it.

This same mindset is also applied by Accelleron through the digital solutions we offer. It is one of the elements that makes our ongoing technical partnership with Sauber Motorsport – the Swiss outfit responsible for running Alfa Romeo F1 Team Stake – a winning combination.

Oliver Riemenschneider, Chairman of the Board at Accelleron explains:

“The interactions in F1 connect different locations and different people with different perspectives in a split second and enable them to make good decisions. In partnership with Sauber, we are saying: ‘this F1 team is working in some interesting new ways; let’s explore if these can apply to the similar challenges we face.’ After all, this sort of connectivity has the power to change how we work as a company.”

Evidence of an F1-like mindset around data can be found already at Accelleron in Tekomar XPERT marine, the integrated software package that allows operators to quickly assess the performance of their engines, emissions and hull efficiency, via an app-based interface that presents KPIs drawn directly from digitized data. In the same way Sauber is chasing thousandths of a second on track, Tekomar XPERT is helping operators achieve sizable percentage efficiency gains making them more competitive on the world market.

But what is digitalization and how can a unique interpretation of it – shared by Accelleron and Sauber – benefit the operational efficiency of F1 teams and marine operators alike?

Cristian Corotto, Accelleron Division President Digital, explains:

“Digitalization is a dynamic and exciting action. It’s about the processes; converting data from analogue information to digital format so it can be rapidly accessed, processed, stored and manipulated to optimise performance – and in our case add value to our customers.”

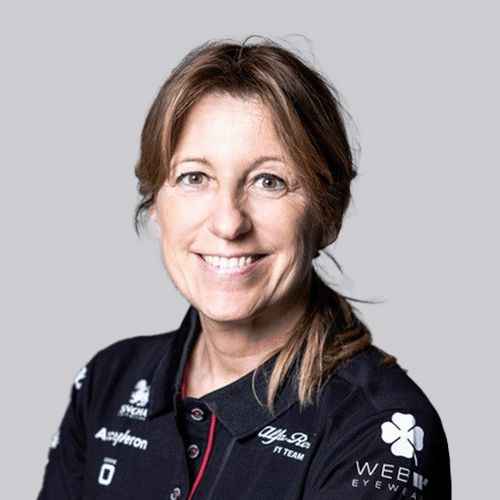

For Cristian’s counterpart at Sauber, Lucia Conconi, Head of Vehicle Performance, digitalization has transformed the way F1 teams go racing, prompted by the massive reductions in track testing in recent decades. Twenty years ago, teams could run as many test sessions as their budgets allowed. But now they are limited to three days at the start of the season, the odd official tyre test, and practice sessions during a Grand Prix weekend.

“Testing restrictions mean we have to rely on our simulator – that Accelleron calls the ‘digital twin’ – a lot,” Lucia says. “During an F1 race weekend, we run the simulator at our Hinwil base in parallel to the cars on track, so we can have a digital twin. The importance of the simulator has increased hugely during the last 10 years.”

When Lucia talks of the simulator, she is referring to a full driver-in-the-loop [DIL] system, with a mock-up of the race car’s cockpit mounted on a six-degrees-of-freedom motion platform. A test driver will drive this rig as if it was the car on track, receiving near-realistic motion cues for acceleration, braking, cornering and even engine vibrations felt through the chassis.

It is a vital engineering tool, powered by a physics model that provides as close a representation of the actual car as possible. It is so accurate that setup adjustments, such as varying spring rates or roll bar settings, can be tested in the simulator, fed with current data gathered in almost real time, and used to inform the decisions of the trackside engineers.

Having the power of the DIL simulator remotely accessible during F1 practice and qualifying sessions, in conjunction with a variety of other simulation and modelling tools, is invaluable. “If there is an issue at the track, it is communicated almost immediately to the factory,” Lucia says. “There, engineers work and do the analysis and simulation to find a solution that the track engineers can then consider, test and put in the car.”

Sauber does have considerable computing power available trackside, via its edge computing capability. But with 250Gb of data harvested during a race weekend from up to 200 sensors on each car, the remote operations room back at base, staffed with 25 engineers, is better placed to truly interrogate this information.

“The track engineers do a first pass of analysis, but their primary role is to look after the operation of the car. They cannot focus as much on the analysis,” Lucia points out. “That is why we do much of it at the factory. Time is at a premium trackside so it’s crucial we use our team in Hinwil effectively.”

In the same way that Sauber’s F1 engineers harness edge computing capabilities at the track alongside remote data analysis back at the factory, Tekomar XPERT software can utilise both on-ship and cloud-based resources, to ensure environmental compliance and propulsion efficiency. The result is that more insightful conclusions can be drawn from the data, far beyond what would be possible onboard a ship.

“Using Tekomar XPERT, we can see how assets are being used,” Cristian says. “And to this we apply our intelligence. We make it smart because we have this information available in port so the customer can see and get recommendations. Our customers need to embrace the journey of digitalization to help them manage the requirements coming from environmental law and the technical and commercial sides. There are so many inputs and data points. Nowadays, if you are not storing, manipulating and acting on that data, you will not be able to make smart decisions.”

Though the world of shipping may run at a slower pace than F1, it is no less competitive and unrelenting. “A [shipping] company, as in F1, is placed in a competitive environment,” Cristian says. “They have to fight for a spot market, they have to find the best price and the best vessel to transport the material. They are competing in the trade of global goods.”

Since it was established in 2022, Accelleron’s technical partnership with Sauber has benefitted both companies thanks to the shared goal of being competitive in their respective arenas. Cristian highlights that Accelleron has found new ways of working after taking inspiration from Sauber. “They have to optimise a car, we work and optimise vessels, and this can only happen if we are learning and using data effectively,” he says. “And that is the area where we found a lot of common ground and passion.”

Whether it is at a racetrack or on the high seas, in the 21st century, data dictates the winners and losers. As Cristian puts it: “The ones who are capable of mastering data to make better decisions will have a competitive advantage.”