TPL Component Upgrades

Improve your competitiveness in 12 hours

TPL Upgrade

Imagine being able to boost your overall engine performance in less than a day. With a TPL component upgrade, you get real fuel consumption reduction combined with reduced thermal wear and tear of the engine and turbocharger. This directly translates into lower operational expenditure – and you get back into the game fast, ahead of the competition, with upgraded performance.

Our TPL turbocharger component upgrade increases the performance of your engines as well as your turbochargers. It’s a plug-and-play solution that only replaces internal components. With no changes to external connections and interfaces, this upgrade can be delivered in just 12 hours.

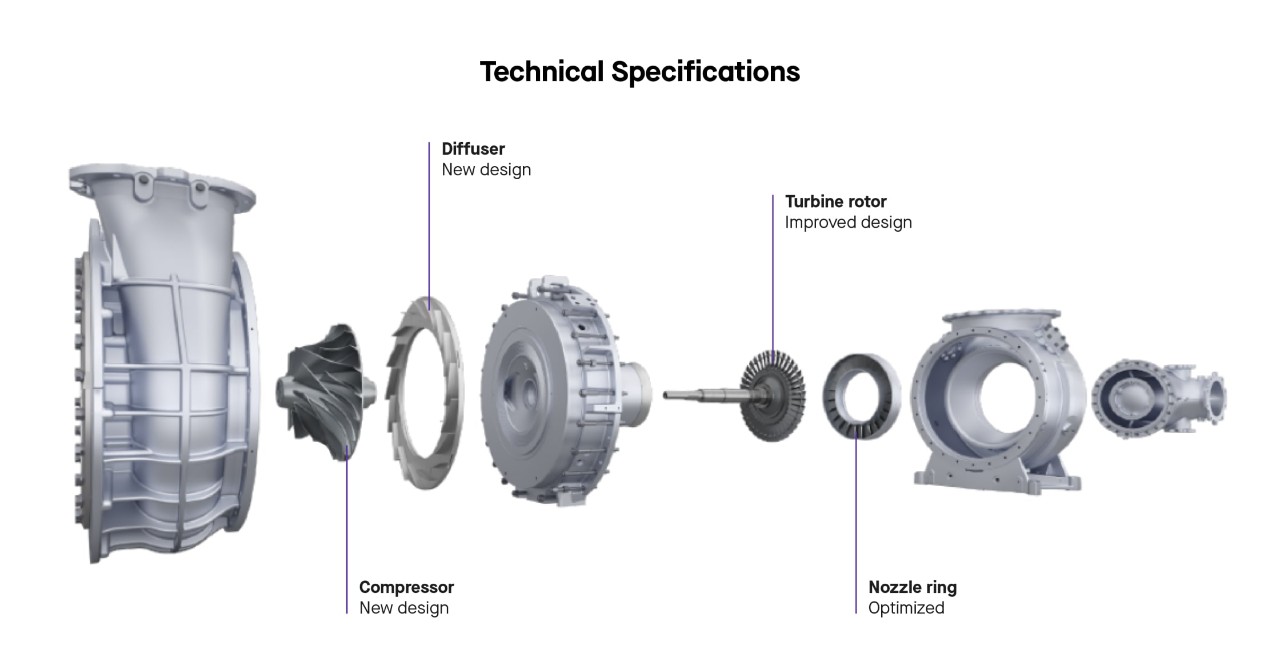

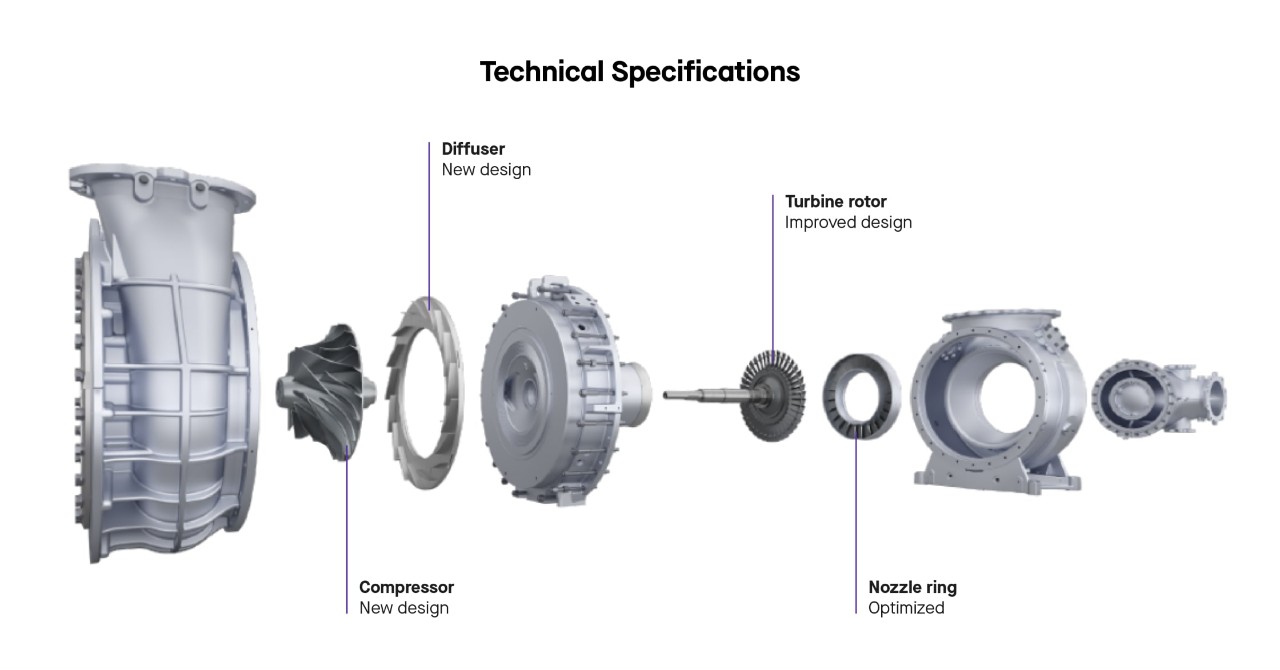

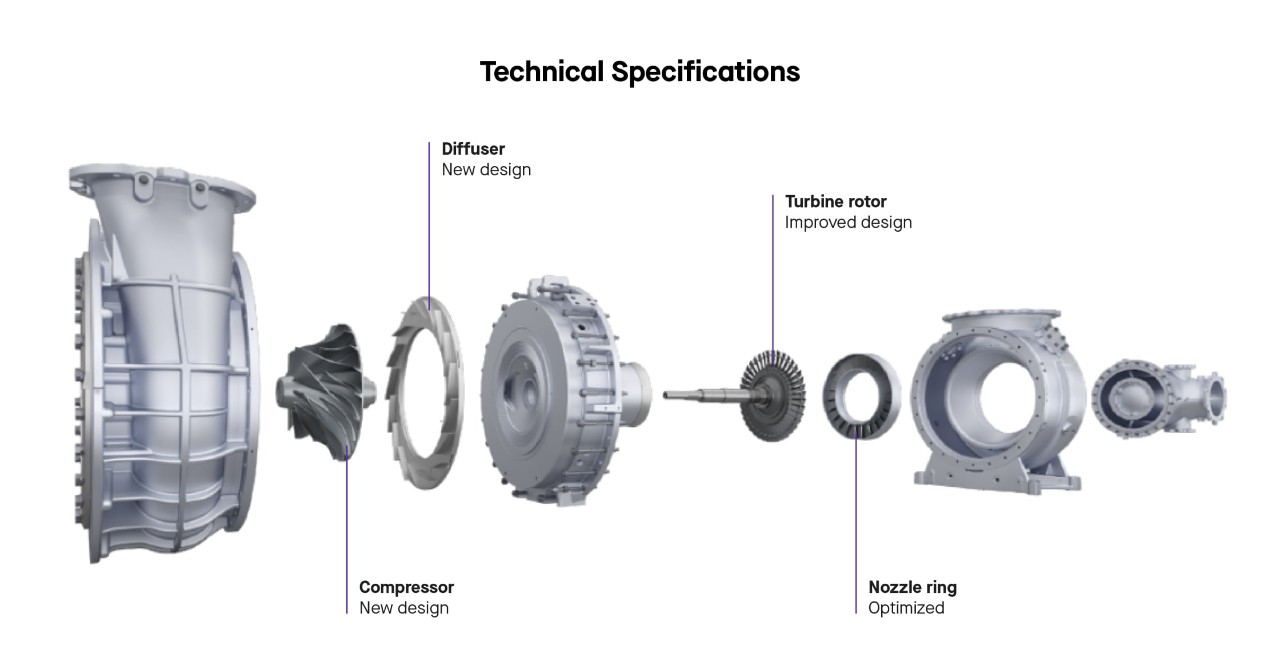

We upgrade the components that make the biggest difference - new compressor wheel and diffusor designs, an improved turbine and nozzle ring, and optimized low friction bearings. Right away, you boost fuel savings and reduce exhaust gas temperatures.

What’s more, the replacement interval of the rotating components is increased by 50%, which further cuts the maintenance costs of the turbocharger.

12 hours. Big gains. Smart choice.

Available Models

- TPL76-C

- TPL73-A

- TPL69-A

Case Study

| Engine | W8L46F with TPL76-C8X |

| Rated engine power | 9’600 kW |

| Major engine load point | 85% |

| Yearly running hours | 5’000 h |

| Fuel savings | 1g/kWh |

| Exhaust gas temperature | 0-15°C |

| Annual added value | |

| Fuel savings (@440$/t HFO) | 18’000 $/year |

Case Study

| Engine | W12V46C with TPL73‑A4X |

| Rated engine power | 12’840 kW |

| Major engine load point | 85% |

| Yearly running hours | 5’000 h |

| Fuel savings | 3.5g/kWh (1) |

| Exhaust gas temperature | 0–50°C (2) |

| Annual added value | |

| Fuel savings (@440$/t HFO) | 75’291 $/year |

(1) In combination with an engine upgrade

(2) Reduction dependant on original design version

Case Study

| Engine | W12V38B with TPL69-A4X |

| Rated engine power | 8’700 kW |

| Major engine load point | 85% |

| Yearly running hours | 5’000 h |

| Fuel savings | 3.5g/kWh (1) |

| Exhaust gas temperature | -20°C (1) |

| Annual added value | |

| Fuel savings (@440$/t HFO) | 57’000 $/year |

(1) In combination with an engine upgrade